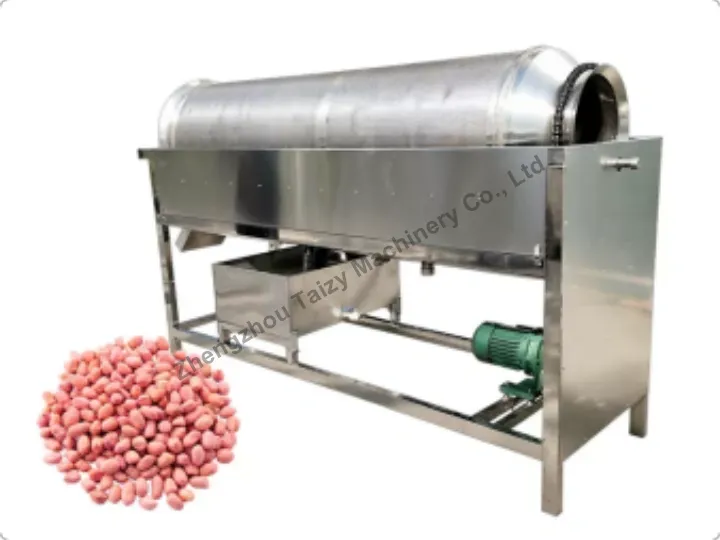

파키스탄의 땅콩 껍질 벗김 기계

파키스탄의 땅콩은 식품, 원재료, 구이 간식, 기름 추출 등 다양한 용도로 사용되는 주요 농산물입니다. 더 가공(껍질 벗김, 로스팅, 페이스트 분쇄 등)에 대한 수요가 증가함에 따라 땅콩 껍질 벗김 기계의 중요성이 커지고 있습니다.

파키스탄의 땅콩 벗김 기계 개발 동향

파키스탄의 농민이나 농장은 단순 원료 수출 또는 판매에서 벗겨 땅콩의 가공(껍질 벗김, 로스팅, 포장)을 통해 부가가치를 높이고 있습니다.

기존의 전통적 수작업 벗김이나 비효율적 설비는 대규모 가공에 더 이상 충분하지 않습니다. 따라서 파키스탄에서 자동화 땅콩 벗김 기계에 대한 수요가 증가하고 있습니다.

파키스탄의 땅콩 껍질 제거기 가격

고객이 땅콩 껍질 벗김 기계를 선택할 때 가격이 중요한 고려 요소가 됩니다. 땅콩 벗김 기계의 가격은 여러 요인에 의해 좌우됩니다:

- 용량 사양: 용량이 클수록 땅콩 껍질 벗기기 비용이 높아집니다. 다양한 생산 규모에 맞는 적절한 기계 모델을 선택해야 합니다.

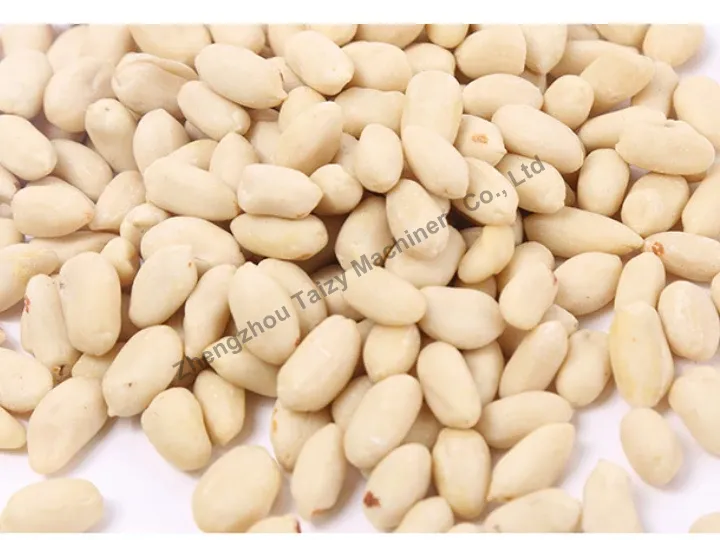

- 기계 성능: 땅콩 껍질 벗기개가 높은 벗겨내기율과 낮은 으깨기율을 달성할 수 있다면, 가공된 제품이 고품질임을 의미하므로 비용이 더 높아집니다.、

- 기계 재료: 식품 접촉 재료(스테인리스 스틸 및 내마모 합금 등)가 선호되며 더 비쌉니다.

- 기계 구조: 땅콩 껍질 제거기는 구조 설계가 뛰어납니다. 유지보수가 쉽고, 긴 수명을 가지며, 초기 투자 비용은 높지만 감가상각과 유지보수 비용은 낮습니다.

가성비 좋은 땅콩 껍질 벗김 기계를 어떻게 선택하나요?

- 생산 용량 요구사항 및 가공 단계 정의

- 먼저 일일 또는 시간당 처리 용량을 추정합니다(하루에 몇 톤의 땅콩 껍질 벗김이 필요한가).

- 농장 현장 작업이나 소규모 처리에는 중소형 모델을, 가공 공장이나 대규모 작업에는 대형 땅콩 껍질 벗김기를 선택하십시오.

- 주요 성능 지표 보기

- 껍질 벗김 속도: 이상적인 속도는 95% 이상입니다.

- 손실률: 낮을수록 좋으며 이상적으로는 5% 이하입니다.

- 소비 및 효율: 고효율 장비는 단위 처리 비용을 감소시킵니다.

- 공급업체 및 서비스 보장 비교

- 국제 물류 및 애프터 서비스를 제공할 수 있는 수출 경험이 있는 브랜드를 선택하십시오.

- 보증 기간, 예비 부품 교체 주기, 원격/현장 지원을 주의하십시오.

왜 Taizy 땅콩 벗김 기계를 선택하나요?

- 고효율: Taizy 땅콩 껍질 벗기기 기계는 시간당 200~1000kg의 생산 능력을 갖추고 있으며, 최대 98%의 껍질 벗기기율을 달성합니다.

- 수출 및 물류 경험: Taizy는 자체 운송 업체와의 파트너십을 유지하여 전 세계로 기계의 원활한 배송을 보장합니다.

- 맞춤형 솔루션: Taizy는 고객의 원자재 특성과 가공 요구 사항(지역별 땅콩 품종, 수분 함량, 전처리 상태, 목표 생산 용량 등)에 따라 맞춤형 솔루션을 제공합니다.

- 종합 서비스: Taizy는 전체 프로세스에 걸쳐 모델 선택 및 구매부터 설치, 시운전, 교육까지 원스톱 지원을 보장하는 완전한 기계 구성과 기술 사양을 제공합니다.

결론

파키스탄에서 땅콩 껍질 벗김 기계가 널리 보급되면서 현지 땅콩 산업의 기계화가 촉진되었을 뿐 아니라 기업에도 더 큰 경제적 이익을 제공했습니다.

효율적이고 내구성 있는 땅콩 벗김 기계를 찾고 있다면 Taizy가 신뢰할 파트너가 되어 드립니다. 맞춤형 솔루션 및 견적을 원하시면 언제든지 연락 주십시오.