Линия для открытия фундука

| Бренд | Тайзи |

| Емкость | 250-600кг/ч |

| Власть | 13.1-18кВт |

| Машина для измельчения маиса | Машина для замачивания, машина для открытия фундука и т. д. |

| Обработка сырья | Фундук |

Теперь вы можете уточнить технические подробности у наших менеджеров проектов.

Линия для открытия фундука — автоматическое решение, объединяющее замачивание, открытие, сушку и упаковку. В основном предназначена для точного прорезания внешней оболочки целых фундуков и последующей сушки и упаковки.

Благодаря многоканальной системе непрерывной работы эта производственная линия может стабильно выдавать 250–600 кг/ч, что подходит для проектов по обработке фундука разного масштаба. Эффективно повышает общую производительность и качество продукции, обеспечивая стабильность результатов очистки.

Преимущества линии обработки фундука

- От замачивания и открытия до сушки и упаковки — вся производственная линия интегрирована, что повышает общую эффективность работы.

- Наша линия для открытия фундука доступна в нескольких конфигурациях. Клиенты могут гибко выбирать между 10, 15 или 20 каналами в зависимости от целевого объема производства.

- Комбинация паровой технологии и специальной структуры экструдирующего диска обеспечивает стабильное открытие фундука. Это облегчает последующую сушку и упаковку.

- Процессы подъема, сортировки, открытия и выгрузки работают непрерывно, что снижает ручной труд и делает линию подходящей для долгосрочного стабильного производства.

Какое оборудование используется для линии открытия фундука?

Наше оборудование для линии очистки и обработки фундука включает в себя:

- Оборудование для замачивания фундука

- Машина для открытия фундука

- Машина для сушки фундука

- Машина для упаковки фундука

Оборудование в этой линии для открытия фундука может быть настроено и выбрано в соответствии с конкретными потребностями.

Машина для замачивания фундука

Бак для замачивания используется для замачивания фундука в теплой воде примерно при 50°C около 30 минут. Это размягчает скорлупу фундука, повышая вероятность успешного открытия и уменьшая количество повреждений.

Машина для открытия фундука

Основная функция машины для открытия фундука — создание равномерного прореза на поверхности целых фундуков. Оборудование оснащено парогенератором, что снижает вероятность повреждения фундука.

Наше оборудование для открытия фундука доступно с 10, 15 и 20 каналами, что позволяет клиентам выбрать наиболее подходящее для их нужд.

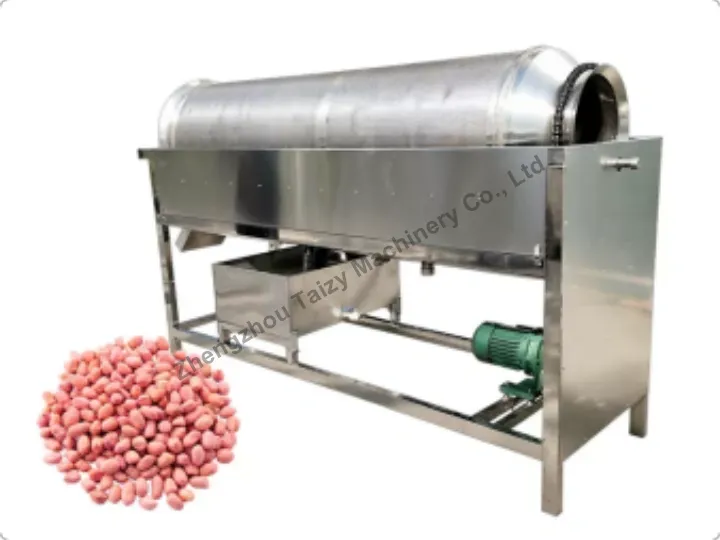

Машина для сушки фундука

После открытия фундука его необходимо высушить в сушильной камере. Процесс сушки эффективно снижает влажность фундука, улучшая его вкус и продлевая срок хранения.

Машина для упаковки фундука

После сушки фундук можно упаковать с помощью вакуумной упаковочной машины. Этот метод упаковки эффективно предотвращает поглощение влаги и окисление, что продлевает срок хранения и повышает качество продукции, делая их пригодными для розничной и экспортной торговли.

Кроме вакуумных упаковочных машин, мы также предлагаем другие виды упаковочного оборудования для фундука, такие как машина для гранулированной упаковки.

Принцип работы линии обработки фундука

- ЗамачиваниеЗамачивание фундука в теплой воде при примерно 50°C около 30 минут.

- ПодачаЗамоченные фундуки заливаются в конвейер, который транспортирует их к бункеру. В бункере есть спиральная подача, которая равномерно распределяет фундук по разным каналам.

- ОткрытиеФундук попадает в открыватель и сжимается двумя прессующими дисками, достигая точного открытия.

- ВыгрузкаОткрытые фундуки автоматически падают на конвейер снизу, входя в последующие процессы сушки или упаковки.

Параметры линии обработки фундука

Наша линия для открытия фундука доступна с 2, 3 или 4 группами, каждая из которых имеет пять каналов. Спецификации следующие:

| Модель | Двухгрупповая | Трехгрупповая | Четырехгрупповая |

| Общая мощность | 13.1кВт | 16кВт | 18 кВт |

| Емкость | 250-300кг/ч | 350-450кг/ч | 500-600кг/ч |

| Испарение | 70-90кг/ч | 80-110кг/ч | 80-110кг/ч |

| Потребление природного газа | 5м³/ч | 7м³/ч | 7м³/ч |

| Потребление сжиженного нефтяного газа | 3.5кг/ч | 5кг/ч | 5кг/ч |

Сколько стоит линия обработки фундука?

Цена линии для открытия фундука не фиксирована и обычно зависит от следующих факторов:

- Конфигурация производственной мощности: Количество комплектов и каналов (10/15/20 каналов) значительно влияет на стоимость оборудования.

- Выбор вспомогательного оборудованияВключение или исключение замачивающих резервуаров, сушильных камер и вакуумных упаковочных машин напрямую влияет на общую стоимость.

- Требования к кастомизацииНапример, стандарты напряжения, уровень автоматизации или особые структурные требования.

- Масштаб линииРазница в цене между отдельным оборудованием и полной производственной линией значительна.

Часто задаваемые вопросы по линии открытия фундука

Какова мощность линии для открытия фундука?

250-600 кг/ч.

Зачем фундуку нужно замачивать перед очисткой?

Замачивание фундука размягчает скорлупу, что помогает повысить успех открытия и снизить количество повреждений.

Температура и время замачивания фиксированы?

Общая рекомендация — замачивать их в теплой воде при примерно 50°C около 30 минут. Можно регулировать в зависимости от типа фундука.

Можно ли настроить производственную линию, используя только часть оборудования?

Да. Производственная линия поддерживает модульную конфигурацию, позволяя клиентам выбирать оборудование в соответствии с их конкретными потребностями.

Можно ли настроить продукт в соответствии с требованиями клиента?

Да. Производственная мощность, стандарты напряжения и расположение оборудования могут быть настроены в соответствии с требованиями проекта.

Свяжитесь с нами, чтобы узнать больше!

Если вы планируете построить или модернизировать линию для открытия фундука, наша команда подберет для вас подходящую конфигурацию оборудования и технологические решения, исходя из вашего целевого объема, сорта фундука и требований к конечному продукту.

Мы можем предоставить вам:

- Полные решения по производству открытых фундуков

- Поддержка в выборе оборудования и технологических процессов

- Руководство по планировке и установке завода

Пожалуйста, свяжитесь с нами, чтобы получить профессиональные рекомендации по конфигурации и подробные технические решения, адаптированные к вашему проекту.