Kakaosmörsproduktionslinje

| Jina | Kakaosmörsproduktionslinje |

| Färdigt produkts finhet | 200mesh |

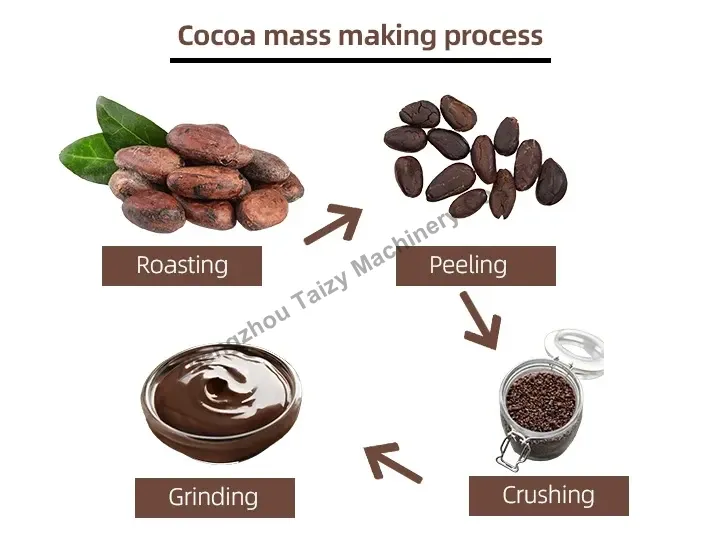

| Mchakato | Rostning→skalning→malning→Homogenisering |

| Krävda maskiner | Kakaoböna roaster, skalare, malare, osv. |

Sasa unaweza kuwauliza wasimamizi wetu wa mradi kwa maelezo ya kiufundi

The cocoa butter production line is a fully automated cocoa paste production unit comprised of multiple machines. It processes cocoa beans into cocoa paste through a multi-step process. Its functions include roasting, peeling, and grinding the cocoa beans into cocoa paste.

Taizy cocoa paste production line has a production capacity of up to 2,000 kg/h. The line includes cocoa roaster, cocoa bean peeler, grinder, and elevator. These machines work in tandem, resulting in significantly higher efficiency.

Egenskaper hos kakaomassaproduktionslinjen

- | Udhibiti kamili wa mstari wote wa kiotomatiki| Kutoka kwa ufungaji wa malighafi, kusaga, kuchanganya, homogenization, kupumzika, kujaza, operesheni zote zinaweza kuendeshwa kiotomatiki ili kupunguza gharama za kazi.

- | Mchakato wa uzalishaji unaoendelea| Mchakato wa mtiririko wa vifaa ndani ya mfumo wa kufungwa, kuzuia uchafuzi na kufanikisha ufanisi wa juu wa uzalishaji.

- | Bidhaa ya mwisho ya ubora wa juu| Paste ya kakao inayozalishwa na mstari wa uzalishaji wa paste ya kakao ni nyembamba zaidi na inakwepa kuunganishwa wakati wa mchakato wa uzalishaji.

- | Imepatikana kwa vifaa vya kiwango cha chakula| Mstari wote umejengwa kwa chuma cha pua au chuma cha kaboni, kinachozuia kutu, rahisi kusafisha, na kinakidhi viwango vya usafi wa mashine za chakula.

- | Mfumo wa usalama wa kuzima moto| Mstari wetu wa kutengeneza siagi ya kakao unaweza kuendeshwa na mfumo wa kuzima moto wa dioksidi kaboni kulingana na mahitaji ya mteja.

Användningar av jordnötssmör

- | Utengenezaji wa chokoleti| Paste ya kakao ni kiungo muhimu katika utengenezaji wa chokoleti na inaweza kutumika kutengeneza bidhaa mbalimbali, ikiwa ni pamoja na chokoleti safi, chokoleti ya maziwa, na chokoleti zilizojaa.

- | Sekta ya mkate| Paste ya kakao inatumiwa sana kama kiambato, mapambo, na viungo katika bidhaa zilizobakiza kama keki, biskuti, mkate, na mousse.

- | Usindikaji wa vinywaji| Paste ya kakao inaweza kutumika kuandaa vinywaji vya kakao, maziwa ya chokoleti, maziwa ya barafu, na vinywaji vya barafu, ikiongeza ladha tajiri na muundo wa mdomo.

- Vyakula vya sukari| Paste ya kakao hutumika sana kwa kufunga, kujaza, na kuifunika bidhaa za sukari, kama vile chips za chokoleti na bonbons.

- Usindikaji wa maziwa| Kampuni nyingi za maziwa hutumia paste ya kakao kuboresha ladha na rangi ya bidhaa kama vile mtindi, barafu, na krimu.

Kakaosmörsproduktionsprocess

The main processes of cocoa butter production include roasting, peeling, grinding, homogenizing, storage, etc.

- Kuchoma| Maharagwe ya kakao yanachomwa kwa usawa ili kuondoa unyevu wa ziada na kuleta harufu ya kakao.

- Kuchubua| Baada ya kuoka, maharagwe ya kakao yanachomwa na kusagwa ili kutenganisha mbegu za kakao na kuondoa uchafu kutoka kwa maganda ili kuhakikisha usafi wa bidhaa iliyomalizika.

- | Kusaga| Piga kakao kwa kutumia mashine ya kusaga ili kutoa mchanganyiko wa kakao wa kina ili kuachilia mafuta yaliyomo, na kuunda muundo wa msingi wa paste ya kakao.

- | Homogenization| Kushughulikia paste ya kakao kwa kutumia homogenizer kunaweza kufanya chembe kuwa nyembamba zaidi na kuboresha ladha.

- | Hifadhi| Paste iliyosafwa ya kakao inahifadhiwa na kulindwa dhidi ya oksijeni katika tanki za kuchanganya, tanki za shinikizo la chini, na chupa za hifadhi.

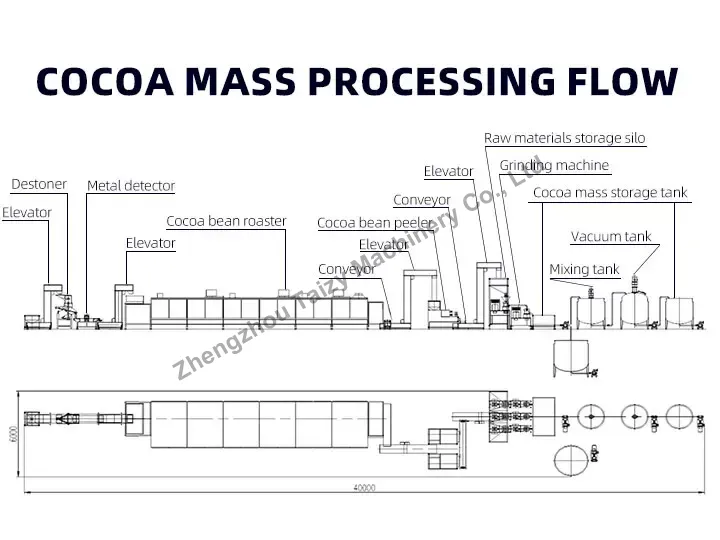

Maskiner i kakaosmörsproduktionslinjen

The machines in the cocoa paste butter processing line include:

- Z-shaped elevator

- Cocoa bean roasting machine

- Cocoa bean peeling machine

- Cocoa bean grinding machine

- Homogenizer

- Cocoa paste storage jar

Z-shaped elevator

In the cocoa butter production line, the Z-shaped elevator is used to automatically load cocoa beans, saving labor and improving production efficiency.

The Z-shaped elevator consists of hopper and Z-shaped conveyor mechanism, using a vibrating feed mechanism. It is made of stainless steel, which is more in line with hygiene standards. Its parameters are as follows:

| Jina la mashine | Z-shaped elevator |

| Nguvu | 0.75kw |

| Ukubwa wa mashine | 2500x700x3000mm |

| Material | Stainless steel |

Kakaorostmaskin

The function of the roaster on cocoa beans is to evenly heat and roast the cocoa beans to remove moisture. In the cocoa paste production line, we use a chain-link roasting machine.

It can be equipped with the siemens control cabinet, which enables precise temperature and time control, automatic start and stop, and fault alarms, ensuring a stable and consistent baking process. Its parameters are as shown below:

| Jina la mashine | Chain-link roaster |

| Nguvu | 30kw |

| Ukubwa wa mashine | 15000x3250x2550mm |

| Material | Carbon steel (customizable stainless steel) |

| Njia ya kupokanzwa | Gas heating and electric heating |

The cocoa bean roasting machine can also be equipped with an optional CO₂ fire suppression system, providing fire protection in high-temperature environments and effectively enhancing equipment operational safety.

Cocoa bean peeling machine

The cocoa bean peeling machine is used to efficiently separate the shells from the cocoa nibs after roasting. The equipment utilizes a three-step system: roller dehulling, vibrating grading and screening, and air separation, working in tandem to achieve the following functions:

- | Utenganishaji wa maganda: Vifuniko vinavyozunguka kwa upole vinashinikiza maharagwe ya kakao kuvunjua maganda yake.

- | Upimaji na usambazaji wa kiwango| Skrini za kupiga kelele husambaza na kuangalia kwa usawa malighafi iliyosagwa, kuboresha ufanisi wa ugawaji.

- | Ugawaji wa hewa| Kwa kurekebisha shinikizo la hewa linalofaa, maganda yanatolewa, na kubaki mbegu za kakao safi.

The machine is easy to operate and offers excellent separation performance, effectively improving the purity of raw materials, and is an important machine in the cocoa butter production line. Its parameters are as follows:

| Mfano | TZ-1 | TZ-2 | TZ-3 | TZ-4 |

| Uwezo | 50-100kg/h | 200kg/h | 300kg/h | 400-500kg / h |

| Nguvu | 0.4kw | 0.75kw | 0.75 | 2.2kw |

| Kiwango cha peeling | / | >98% | >99% | >99% |

| Machine wieght | / | 140kg | 200kg | 280kg |

Cocoa bean grinding machine

The cocoa paste grinder uses high-speed relative motion between the stator and rotor to rub and grind the cocoa beans. This process breaks down the cell walls, releasing the cocoa paste, ultimately creating an extremely fine and smooth liquid paste. The grind fineness can reach 200 mesh.

Its parameters are as listed below:

| Jina la mashine | Cocoa bean grinding mahcine |

| Nguvu | 30kw |

| Ukubwa wa mashine | Cocoa bean grinding machine |

Homogenizer

The cocoa paste homogenizer is one of the equipment in the cocoa butter production line. It is mainly used to further homogenize the ground cocoa paste. This process makes the particles in the cocoa paste finer and more evenly distributed, thereby improving the smoothness and taste of the cocoa paste.

Its parameters are as follows:

| Jina la mashine | Homogenizer |

| Nguvu | 37kw |

| Ukubwa wa mashine | 1350*1200*1520mm |

| Material | 304 chuma cha pua |

Cocoa paste storage jar

The cocoa paste storage system consists of mixing jar, vacuum jar, and storage jar. It is used for constant temperature storage, anti-oxidation, and anti-stratification of cocoa paste. It is an important post-processing equipment in the cocoa butter production line.

- The mixing tank is mainly used to maintain the uniformity of the cocoa paste.

- Vacuum tanks are used to degas and prevent oxidation of cocoa paste.

- The storage tank serves as a temporary holding vessel for cocoa paste at the end of the production line. Its primary function is to ensure continuous filling operations.

FAQ om kakaosmörproduktionslinje

How fine can cocoa paste be?

200 mesh.

Is the equipment operation complicated?

Easy to operate. Equipped with a PLC touch screen control system, one-button start or stop.

What are the heating methods of the toaster?

Electric heating and gas heating. It is recommended to use gas heating (more economical than electric heating)

Can the cocoa butter production line be customized?

Yes. We can customize a complete line solution based on your production volume, site layout, and other factors, providing layout design and technical guidance.

Varför välja Taizy som din föredragna leverantör?

- | Uzoefu mkubwa wa tasnia| Taizy ina uzoefu wa miaka katika vifaa vya paste ya kakao na chokoleti, na imefanikiwa kuwasilisha mistari ya uzalishaji yenye ufanisi kwa wateja katika mataifa na mikoa mbalimbali duniani kote.

- | Vifaa vya ubora wa juu na teknolojia| Vifaa vinatumia vifaa vya kiwango cha chakula, vinatoa upinzani wa kutu na rahisi kusafisha. Teknolojia za hali ya juu za homogenization, kusaga, na udhibiti wa moja kwa moja zimeunganishwa.

- | Usalama wa uzalishaji| Wateja wanaweza kuchagua kuweka mfumo wa kuzima moto kwa gesi ya dioksidi kaboni au gesi isiyozuia kwa ufanisi wa kuzuia moto na usalama wa uzalishaji.

- | Uboreshaji wa desturi na ufanisi| Tunatoa miundo ya kibinafsi na suluhisho zilizobinafsishwa kulingana na mahitaji ya wingi wa uzalishaji wa mteja, mapishi ya mchakato, na mipangilio ya tovuti.

- Omfattande eftermarknadsstöd| Tunatoa mafunzo ya uendeshaji, msaada wa kiufundi, na huduma za matengenezo. Zaidi ya hayo, tunaweza kubuni michoro ya mpangilio wa mashine inayolingana na kiwanda chako.

Contact us now!

Taizy offers efficient, automated cocoa butter production lines. We also provide a variety of food processing solutions, including peanut butter production line and peanut oil production line.

Our team of experts is always available to provide free technical consultation and customized solutions, tailoring the most optimal production plan to your needs. Contact us today and let Taizy help you efficiently produce high-quality food products and enhance your market competitiveness.