包衣花生生产线

| 品牌 | 泰兹 |

| 加工步骤 | 烘烤→去壳→涂层→烘焙→冷却→调味→包装 |

| 所需设备 | 花生烘烤机、花生去壳机、花生涂层机、花生冷却机等。 |

| 适用原料 | 花生、腰果、蚕豆、夏威夷果、药丸等 |

您现在可以向我们的项目经理询问技术细节

涂层花生生产线是一套自动化设备系统,用于将生花生加工成涂层调味成品。该生产线可连续完成烘烤、去壳、涂层、烘焙成型、冷却、调味和包装等全部工艺。

除了加工花生外,我们的涂层花生生产线还适用于蚕豆、腰果、夏威夷果甚至药丸。该生产线具有自动化程度高、劳动成本低等显著优势,是坚果加工企业的理想设备。

涂层花生加工线的优势

- 高度自动化生产

- 我们的涂层花生生产线连续运行,减少人工干预,大大降低劳动成本。

- 品质稳定

- 涂层花生生产线可精确控制温度、时间、转速和配料比例。

- 广泛适用

- 可用于加工各种颗粒状物料,如花生、腰果、榛子和药丸等。

- 符合食品加工标准

- 涂层花生生产线采用食品级材料制造,其结构设计符合食品加工卫生要求。

- 定制生产

- 整个花生涂层线可以根据客户需求定制,如产量和机器配置。

适用原料

除了花生外,该涂层花生生产线还可用于加工多种坚果和休闲食品,应用范围广泛。可加工材料包括:花生、青豆、豌豆、蚕豆、腰果、杏仁、榛子及其他可涂粉的坚果或豆类。

涂层花生生产线工艺流程

整个生产线采用连续加工,主要工艺如下:

烘烤→去壳→涂层(可选油喷)→成型烘焙→冷却→调味→包装

花生涂层生产线设备

本涂层花生生产线包括以下设备:

- 花生炒货机

- 花生剥皮机

- 裹粉花生机

- 花生油喷涂机

- 摇炉

- 花生冷却机

- 花生调味机

- 涂层花生包装机

以上为常见的机器配置。涂层花生加工线的产能和机器配置可根据客户需求调整。

花生炒货机

花生烘烤机用于降低花生的水分含量,增强其自然风味。该机器采用电加热、燃油、天然气或煤作为热源,具有自动温控和设定功能。

该花生烘烤机操作简便、高效、节能、耐用。其规格如下:

| 模型 | 尺寸(毫米) | 产能(公斤/小时) | 功率(千瓦) | 电加热(千瓦) | 燃气加热(公斤) |

| TZ-1 | 3000*1200*1700 | 80-120 | 1.1 | 22 | 2-3 |

| TZ-2 | 3000*2200*1700 | 180-250 | 2.2 | 35 | 3-6 |

| TZ-3 | 3000*3300*1700 | 280-350 | 3.3 | 45 | 6-9 |

| TZ-4 | 3000*4400*1700 | 380-450 | 4.4 | 60 | 9-12 |

| TZ-5 | 3000*5500*1700 | 500-650 | 5.5 | 75 | 12-15 |

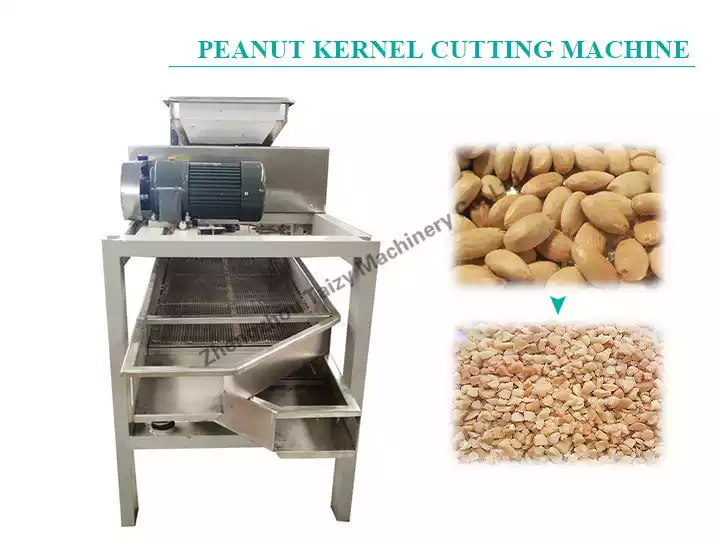

花生脱皮机

花生去壳机的功能是去除烘烤后花生的红皮。我们的花生去皮机采用滚动摩擦方式,具有使用寿命长、去皮效果好、产量高等优点。详细信息如下:

| 完整率 | ≥96% |

| 方面 | 1100*400*1000毫米 |

| 容量 | 200-250公斤/小时 |

花生涂层机

花生涂层机是生产线中最关键的设备。花生在旋转鼓中不断翻滚,通过喷涂和撒粉形成均匀的外壳。

| 模型 | 转速 | 传输功率 | 风扇功率 | 底部加热功率 | 热风功率 | 容量 | 机器尺寸 |

| TZ-400 | 28r/min | 0.37千瓦 | 180w | 1千瓦 | 1千瓦 | 2-5kg/批 | 900*500*1450mm |

| TZ-600 | 28r/min | 0.75kw | 180w | 1千瓦 | 1千瓦 | 5-10kg/批 | 900*600*1450mm |

| TZ-800 | 28r/min | 1075kw | 250w | 2kw | 2kw | 10-20kg/批 | 1000*800*1500mm |

| TZ-1000 | 28r/min | 0.75kw | 250w | 2kw | 2kw | 20-30kg/批 | 1200*1000*1700mm |

| TZ-1200 | 22r/min | 1.1kw | 250w | 2kw | 2kw | 30-40kg/批 | 1300*1200*1800mm |

| TZ-1400 | 22r/min | 1.5千瓦 | 250w | 3kw | 3kw | 40-50kg/批 | 1550*1400*1850mm |

花生油喷涂机

油喷系统可与涂层机配合使用,其功能是增加光泽和改善质感。喷油量可精确调节,防止油料浪费。

摇炉

旋转烤箱用于烘烤花生并固化表面涂层,其功能是固化涂层并形成酥脆的口感。

花生冷却机

烘烤后,花生需转移至花生冷却机冷却。此过程能迅速将花生冷却至室温,防止吸湿。

| 模型 | 产能(公斤/小时) | 风扇功率(千瓦) | 电压 | 尺寸(毫米) |

| TP-1 | 200-300 | 1.1 | 380V/220V 50Hz | 1300*600*600 |

花生调味机

花生调味机可以充分混合花生和调味料。我们的机器可以连接外部喷涂装置或手动投料。用户可根据需要添加所需调味料。

| 力量 | 1.1千瓦/380伏 |

| 重量 | 150公斤 |

| 方面 | 1000*800*1300毫米 |

| 桶径 | 1000毫米 |

| 容量 | 300kg/h |

涂层花生包装机

成品涂层花生可以用颗粒包装机进行包装。我们的颗粒包装机适用于包装坚果、干果、糖果及其他颗粒物品。

| 袋型 | 背封(可定制) |

| 包装速度 | 30-72包/分钟或50-100包/分钟 |

| 袋长 | 30-180毫米 |

| 灌装范围 | 22-220毫升 |

| 功耗 | 1.8千瓦 |

| 重量 | 250公斤 |

| 方面 | 650*1050*1950毫米 |

| 纸箱尺寸 | 1100*750*1820毫米 |

涂层花生生产线常见问题

一条生产线需要多少工人?

2-4人。

是否生产多种口味?

是的,通过更换涂层配方和调味粉。

是否可以定制电压和机器配置?

电压和配置可以定制。

涂层花生生产线符合食品加工标准吗?

是的,整个生产线采用食品级材料制造。

是否提供安装和售后服务?

我们提供安装指导和延长的售后服务期。

为什么选择 Taizy 作为您的供应商?

- 定制生产线方案

- 根据产量、预算和工厂布局进行个性化设计。

- 一站式设备供应

- 从单机到完整的涂层花生生产线,我们提供一体化解决方案,节省采购和沟通成本。

- 全方位售前售后服务

- 提供安装指导、技术培训和长期备件支持

- 丰富的出口经验

- 我们的设备销往全球,质量稳定可靠。

无论您是计划建设新的花生涂层加工项目,还是想升级现有的涂层花生生产线,我们都能为您提供专业的整线解决方案和详细报价。欢迎随时联系我们获取更多信息!