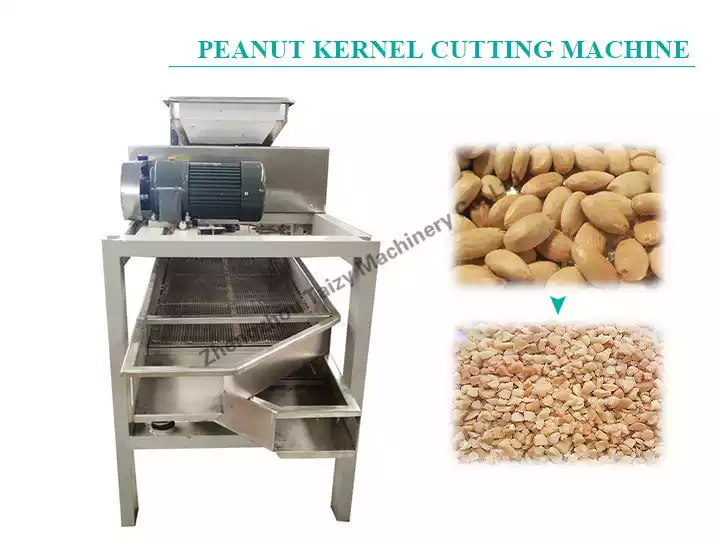

Máquina cortadora de granos de maní

| Marca | Taizy |

| Tipo de máquina | Tipo de cuchilla recta, tipo de doble rodillo |

| Fuerza | 0.93-2.25kw |

| Capacidad | 100-300kg/h |

| Solicitud | Cacahuetes, nueces de macadamia, avellanas, anacardos, etc. |

Ahora puede solicitar detalles técnicos a nuestros jefes de proyecto

La máquina cortadora de cáscara de cacahuete se utiliza para procesar cacahuetes en gránulos. Además de cacahuetes, también es adecuada para avellanas, nueces, almendras y anacardos. Ofrecemos dos tipos de máquinas cortadoras de cacahuete: de cuchilla recta y de doble rodillo. Su capacidad de producción varía de 100 a 300 kg/h.

La máquina de picado de cacahuetes Taizy está fabricada en acero inoxidable y otros materiales duraderos, garantizando una producción estable y higiénica. Ofrece alta eficiencia, operación sencilla y una larga vida útil. Si está interesado en esta máquina, ¡no dude en contactarnos!

Ventajas de la máquina cortadora de cacahuetes

Nuestra máquina de corte de núcleo de maní ofrece las siguientes ventajas:

- Tamaño de partícula controlable: Espacio de corte ajustable para cumplir con diferentes especificaciones

- Corte uniforme: Reduce eficazmente las variaciones en el tamaño de las partículas

- Reducción de fugas de aceite: El proceso de corte estable minimiza la extrusión de aceite

- Diseño de grado alimentario: Las partes clave de contacto cumplen con los requisitos del procesamiento de alimentos

- Fácil operación: Estructura razonable, mantenimiento y limpieza convenientes

Escenarios de aplicación de la máquina de corte de núcleo de maní

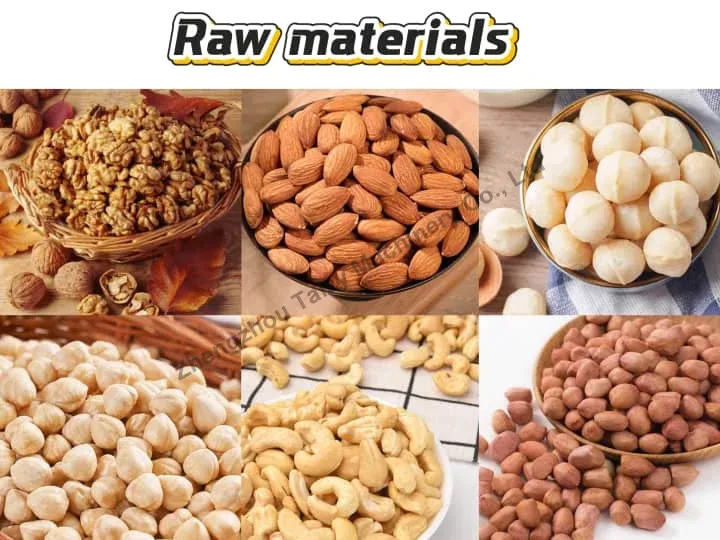

Materias primas procesables

La máquina cortadora de cacahuetes se utiliza principalmente para cortar nueces con alto contenido de aceite y textura dura. Tiene una amplia gama de aplicaciones y puede procesar materias primas comunes, incluyendo cacahuetes, almendras, anacardos, avellanas, nueces y otros similares.

Escenarios de aplicación

La máquina de picar cacahuetes es adecuada para diversas aplicaciones de procesamiento de alimentos, incluyendo:

- Procesamiento de cacahuetes picados y gránulos de cacahuete

- Procesamiento de materias primas para caramelos y chocolates

- Ingredientes para productos horneados

- Pasos de preprocesamiento para condimentos y mantequilla de maní

- Procesamiento de mezclas de nueces

Dos tipos de máquinas de picado de cacahuetes

Taizy ofrece dos tipos de máquinas de corte de núcleo de maní:

- Máquina de cortadora de cacahuetes de cuchilla recta

- Cortador de cacahuetes de doble rodillo

Tipo 1: Máquina de picado de cacahuetes de cuchilla recta

Principio de funcionamiento

Después de ingresar por la tolva, el material se transporta a la zona de corte mediante una cinta transportadora de PVC de grado alimentario dentro de la tolva. Tras ser cortados por cuchillas de alta velocidad, las partículas calificadas se descargan directamente, mientras que el material no calificado pasa por un segundo proceso de corte.

Características principales

- La estructura de corte de cuchilla recta garantiza un corte estable.

- Ranura de corte ajustable, adecuada para diferentes tamaños de pellet.

- El espacio de corte ajustable acomoda varios tamaños de partículas.

- La cinta transportadora de PVC de grado alimentario cumple con los requisitos del procesamiento de alimentos.

Parámetros técnicos

| Capacidad | Voltaje | Fuerza | Tamaño | Peso |

| 200-300kg/hora | La cinta transportadora de PVC de grado alimentario cumple con los requisitos del procesamiento de alimentos. | 2.25kw | 2.25*1.05*1.4m | 400kg |

Tipo 2: Máquina de picado de cacahuetes de doble rodillo

Principio de funcionamiento y características principales

La máquina de corte de núcleo de maní de doble rodillo consta de dos cuchillas giratorias con espacios ajustables. Corta cacahuetes en partículas pequeñas mediante una combinación de procesos de apretado y corte. Este cortador de maní está equipado con un mecanismo de rasqueta, ofreciendo las siguientes ventajas:

- Prevenir que el material se pegue a la superficie de la cuchilla

- Reducir la oleosidad durante el procesamiento

- Mejorar la estabilidad de operación del equipo

Parámetros técnicos

| Modelo | Capacidad | Voltaje | Fuerza | Dimensión | Peso |

| TZ-1 | 100-200kg/h | La cinta transportadora de PVC de grado alimentario cumple con los requisitos del procesamiento de alimentos. | 0.93kw | 1.6*0.8*1.5m | 300 kilos |

¿Cuánto cuesta una máquina de corte de núcleo de maní?

El precio de la máquina de corte de núcleo de maní no es fijo y está principalmente influenciado por los siguientes factores:

- Tipo de equipo (tipo de cuchilla recta/tipo de doble rodillo)

- Capacidad de producción

- Diferencias de configuración (número de pantallas, material, marca del motor)

- Requisitos de voltaje y personalización

En general, la máquina de corte de núcleo de maní con mayor capacidad de producción y funciones más completas tendrá un precio más alto, pero también generará mayores retornos.

¿Por qué elegir Taizy como su proveedor?

Al elegir la máquina de corte de núcleo de maní, el equipo en sí es importante, pero la experiencia y las capacidades de servicio del proveedor son igualmente cruciales. Aquí te explicamos por qué deberías elegir a Taizy como tu proveedor:

- Taizy tiene muchos años de experiencia en exportación y fabricación de equipos de procesamiento de nueces, y sus productos han servido a clientes del procesamiento de alimentos en muchos países y regiones.

- En cuanto al servicio, ofrecemos un proceso completo desde la evaluación de necesidades hasta el soporte postventa.

- Para diferentes necesidades de procesamiento, Taizy soporta servicios personalizados, como configuración de voltaje.

- Taizy puede ofrecer soluciones completas de equipos de procesamiento de nueces, incluyendo no solo cortadoras de cacahuetes sino también tostador de maní, peladora de maní, y otros equipos relacionados.

Elegir Taizy significa más que comprar una máquina; significa obtener una solución de procesamiento que se adapte mejor a sus necesidades de producción.

¡Contáctenos para más información!

Si busca una máquina de corte de núcleo de maní u otro equipo de procesamiento de nueces, por favor contacte con Taizy para más información. Proporcionaremos asesoramiento y soporte claros según sus necesidades específicas para ayudarle a mejorar la eficiencia de producción.