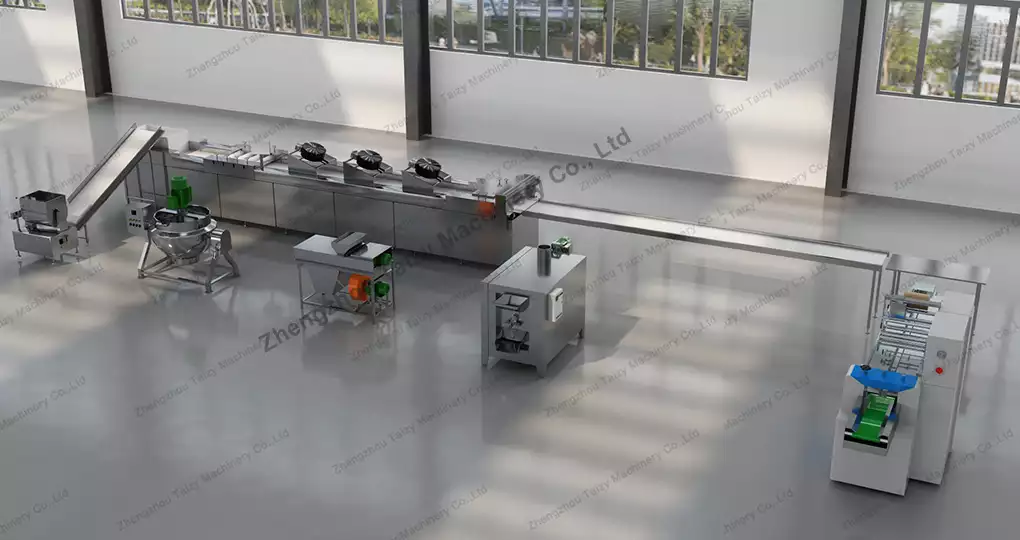

Ligne de production de barres cassantes aux arachides

Machine de fabrication de chikki aux arachides pour produire des bonbons aux arachides

Marque: Taizy

Processus de production : torréfaction des arachides→épluchage→fusion du sucre→mélange→formation de barre de chikki de cacahuète moulu→emballage

Rendement : 50-500kg/h

Produit final : barre de friandises à base d’arachides, Sachima, confiserie au sésame, barre céréalière, barre énergétique, etc.

La ligne de production de barre de cacahuètes caramélisées Taizy est un système d’équipements complet conçu pour la production par lots et à haute efficacité de confiseries à base d’arachides, barre de sésame, Sachima, etc. Elle a une capacité de 50-500kg/h.

L'ensemble de la ligne de production de barres de céréales se compose d'un torréfacteur d'arachides, d'une machine à éplucher, d'un fondoir à sucre, d'un mélangeur, d'une machine de formage et d'une machine d'emballage. Il est hautement automatisé et facile à utiliser, ce qui améliore considérablement l’efficacité de la production et réduit les coûts de main-d’œuvre. La taille des barres cassantes aux arachides peut être personnalisée.

Notre machine de fabrication de chikki aux arachides est populaire dans le monde et a été exportée au Liban, au Canada, à la Dominique, aux États-Unis, aux Émirats arabes unis, etc. Si vous êtes intéressé, n'hésitez pas à nous contacter à tout moment !

Étapes de la ligne de machines de fabrication de chikki aux arachides Taizy

Le processus de production de barre de confiserie aux arachides comprend torréfaction des arachides→pelage→fusion du sucre→mélange→formation de la confiserie à base d’arachides→emballage. Voir ci-dessous pour plus de détails.

Torréfacteur de cacahuètes

Dans la chaîne de production de bonbons aux arachides, cette machine est utilisée dans un premier temps.

La torréfaction des cacahuètes peut stimuler l’arôme des cacahuètes, c’est pourquoi les collations aux cacahuètes sont généralement grillées puis transformées.

Il existe différents modèles de machines à rôtir les cacahuètes, la plage de sortie est de 80 kg/h à 700 kg/h.

| Modèle | Taille | Capacité | Moteur | Pouvoir | Image |

| TZM-1 | 3*1,2*1,7m | 80-120kg/h | 1,1 kW | 18 kW |  |

| TZM-2 | 3*2,2*1,7m | 180-250kg/heure | 2,2 kW | 35 kW |  |

| TZM-3 | 3*3,3*1,7m | 280-350 kg/heure | 3,3 kW | 45 kW |  |

| TZM-4 | 3*4,4*1,7m | 380-450 kg/heure | 4,4 kW | 65 kW |  |

| TZM-5 | 3*5,5*1,7m | 500-700 kg/h | 5,5 kW | 75 kW |  |

Machine à éplucher les cacahuètes

La machine adopte la méthode sèche pour éliminer complètement la peau des cacahuètes. Le noyau de cacahuète après avoir retiré la peau rouge est très propre.

Il a un taux de nettoyage de 96% et une capacité de 200 à 600 kg/h.

| Modèle | TZ-4 | TZ-8 | TZ-12 |

| Pouvoir | 0,75 kW | 1,5KW | 2,61 kW |

| Taille | 1100*400*1100 | 1100*600*1100 | 1180*900*1100 |

| Poids net | / | 200KG | 300KG |

| Poids brut | / | 260KG | 370KG |

| Rendement | 200kg/h | 400kg/h | 600kg/heure |

| Taux de propreté | 96% | 96% | 96% |

| Taux demi-grain | 5-20% | 5-20% | 5-20% |

Pot à sucre

Dans cette étape de la chaîne de production de barres cassantes aux arachides, il s’agit principalement de chauffer et de faire fondre le sucre.

Cette machine est en acier inoxydable et peut chauffer et remuer en même temps.

Trois modes de chauffage sont disponibles : l'électricité, le gaz (gaz naturel, gaz liquéfié, biogaz) et la vapeur.

Vous pouvez choisir un modèle approprié de 50 à 2 000 L.

| Modèle | Poids du corps principal (casserole, base, etc.) | Poids de la pièce d'agitation | Poids du couvercle | Poids de l'armoire de commande électrique |

| 100L | 90 kg | 40 kg | 7 kg | 5 kg |

| 200L | 110 kg | 50 kg | 8 kg | 7 kg |

| 300L | 130 kg | 60 kg | 10 kg | 7 kg |

| 400L | 140 kg | 70 kg | 15 kg | 8 kg |

| 500L | 150 kg | 80 kg | 20 kg | 8 kg |

| 600L | 160 kg | 90 kg | 30 kg | 8 kg |

Mélangeur de bonbons aux cacahuètes

Cette étape consiste à bien mélanger les cacahuètes pelées avec le sucre fondu. Le mixeur peut les mélanger rapidement et uniformément.

Il est équipé d’un dispositif de contrôle de la température pour contrôler la température des matières premières. L'intérieur de la machine a également pour fonction de conserver la chaleur.

Machine de formage de chikki aux arachides

Dans la chaîne de production de barres cassantes aux arachides, cette machine de fabrication de bonbons aux arachides est la pièce maîtresse et peut presser les bonbons aux arachides pour leur donner forme. Il fonctionne toujours avec le cutter pour obtenir les barres cassantes aux arachides de la taille requise.

Lors de l'achat de la machine, vous devez nous indiquer la taille (longueur, largeur et hauteur) du produit que vous souhaitez. Nous vous le recommanderons et le personnaliserons en fonction de vos besoins.

| Modèle | QY-SCX01 |

| Puissance totale de l'hôte | 380 V/50 HZ 1,5 KW, 220/50 HZ 2,5 KW |

| Spécification | 8000*1300*1200mm |

| Poids de l'hôte | 1050 kg |

| Rendement | 50-500 kg/h |

| Poids du produit fini | 5g-300g |

Machine d'emballage de bonbons aux arachides

La machine d'emballage d'oreillers Taizy est utilisée pour emballer des bonbons aux arachides coupés avec une vitesse d'emballage de 5 à 200 sacs par minute.

Nous pouvons vous recommander la bonne machine d’emballage pour l’ensemble de votre ligne de production de barres cassantes aux arachides.

Avantages de la ligne de production de barres cassantes aux arachides Taizy

Automatisation à haute efficacité pour augmenter la capacité de production

Du traitement des matières premières, du mélange au moulage et à la découpe, l'ensemble du processus se déroule efficacement, ce qui améliore considérablement l'efficacité de la production. Cette conception peut aider les clients à réduire les coûts de main-d'œuvre et à répondre à la demande de production de masse, ce qui convient parfaitement aux entreprises de transformation alimentaire à grande échelle.

Qualité du produit stable et goût constant

Les équipements de base, tels que la marmite à sirop, la machine de moulage et la machine de découpe, utilisent des systèmes de contrôle de précision pour garantir que chaque lot de bonbons aux arachides a le même goût, la même forme et la même taille. Il répond à la forte demande du client en matière de qualité des produits. Pour les clients, cette stabilité contribue à améliorer la réputation de la marque.

Matériau sûr, garantie alimentaire

La ligne de production est en acier inoxydable 304, résistant à la corrosion, facile à nettoyer et conforme aux normes internationales d'hygiène alimentaire. Cette conception est tout à fait conforme aux exigences strictes des clients en matière de sécurité alimentaire et aide les clients à profiter de la concurrence sur le marché.

Operation simple et maintenance facile

La ligne de production de barres cassantes aux arachides Taizy est conçue pour être simple et facile à utiliser, afin que même les travailleurs inexpérimentés puissent démarrer rapidement. De plus, l'équipement est facile à entretenir et les pièces sont faciles à remplacer, ce qui aide les clients à réduire les coûts d'exploitation ultérieurement.

Personnalisation flexible pour répondre à des besoins diversifiés

L'usine de transformation de bonbons aux arachides peut être personnalisée en fonction des besoins des clients, tels que différentes formes de bonbons aux arachides, les sorties ou l'ajout d'autres modules fonctionnels. Cette flexibilité peut aider les clients à élargir leurs gammes de produits et à répondre aux besoins des différents marchés.

Système complet de service après-vente

Nous fournissons à nos clients un service après-vente complet, comprenant la mise en service des équipements, la formation au fonctionnement, l'assistance technique, etc. Tant que les clients achètent notre équipement, ils peuvent profiter de notre service attentif pour assurer le fonctionnement stable de la ligne de production.

Matières premières et produits finaux de la ligne de production de barres cassantes aux arachides

La formule de chaque producteur de bonbons aux cacahuètes est différente. Le rapport sucre/cacahuètes est différent et le goût sera différent. Les matières premières courantes pour les barres chocolatées aux arachides sont :

- Cacahuètes : les cacahuètes de haute qualité qui ont été tamisées, nettoyées et torréfiées constituent la matière première de base pour la production de bonbons aux cacahuètes.

- Sucre : le sucre blanc granulé ou le maltose est couramment utilisé comme liant pour donner à la barre cassante aux arachides une saveur sucrée et une texture dure.

- D'autres ingrédients auxiliaires : des graines de sésame, de la noix de coco ou des noix peuvent être ajoutés selon les besoins pour rehausser le goût et la saveur.

Le produit final fabriqué par une ligne de production de barres de céréales aux bonbons aux arachides se compose généralement de :

Mor- ceaux de confiserie à base d’arachides, barre de chikki, barre au sésame, barre énergétique, Sachima, friandises au caramel, barre de riz, etc.

Quel est le prix de la ligne de traitement de barres chocolatées aux arachides ?

Le prix de la gamme de machines de fabrication de chikki aux arachides dépend principalement de la configuration de l'équipement, de la demande de production et des exigences de personnalisation du client. Plus vous souhaitez de configuration d’équipement et plus vous avez de rendement, plus le prix sera élevé.

Lorsque vous achetez, si vous souhaitez connaître le prix spécifique de la machine, n'hésitez pas à nous contacter. Nous vous recommanderons la configuration optimale en fonction de vos besoins et vous enverrons un devis gratuit.

Contactez-nous pour plus de détails!

Si vous êtes intéressé par notre ligne de production de barres cassantes aux arachides ou si vous avez des questions, n'hésitez pas à nous contacter !

Notre équipe expérimentée peut personnaliser la solution selon vos besoins et vous aider à construire une ligne de production de barres de céréales efficace. Qu'il s'agisse de la sélection des équipements, des modalités de transport ou du service après-vente, nous vous accompagnerons tout au long du processus pour garantir que votre production se déroule sans souci.