मूंगफली भंगुर बार उत्पादन लाइन

मूंगफली कैंडी उत्पादन के लिए मूंगफली चिक्की बनाने की मशीन

Brand: Taizy

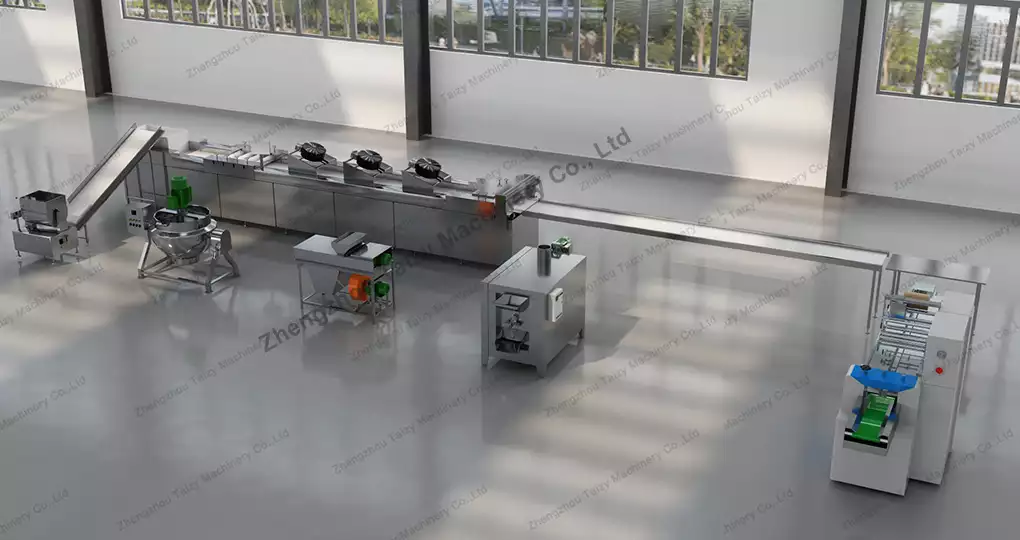

उत्पादन प्रक्रिया: मूंगफली भूनना→छिलना→चीनी पिघलाना→मिक्सिंग→ग्राउंडनट चिक्की फॉर्मिंग→पैकिंग

उत्पादन क्षमता: 50-500 किलोग्राम/घंटा

अंतिम उत्पाद: मूंगफली की कैंडी बार, सचिमा, तिल की कैंडी, अनाज बार, ऊर्जा बार, आदि।

Taizy मूंगफली की टॉफी बार उत्पादन लाइन मूंगफली की कैंडी, तिल की बार, सचिमा, आदि के बैच और उच्च-क्षमता उत्पादन के लिए डिज़ाइन किया गया एक पूर्ण उपकरण प्रणाली है। इसकी क्षमता 50-500 किलोग्राम/घंटा है।

संपूर्ण अनाज बार उत्पादन लाइन में मूंगफली भूनने की मशीन, छीलने की मशीन, चीनी पिघलाने वाला बर्तन, मिक्सर, बनाने की मशीन और पैकिंग मशीन शामिल हैं। यह अत्यधिक स्वचालित और संचालित करने में आसान है, जो उत्पादन क्षमता में उल्लेखनीय सुधार करता है और श्रम लागत को कम करता है। मूंगफली भंगुर सलाखों के आकार को अनुकूलित किया जा सकता है।

हमारी मूंगफली चिक्की बनाने की मशीन दुनिया में लोकप्रिय है और इसे लेबनान, कनाडा, डोमिनिका, संयुक्त राज्य अमेरिका, संयुक्त अरब अमीरात आदि में निर्यात किया गया है। यदि आप रुचि रखते हैं, तो किसी भी समय हमसे संपर्क करने के लिए आपका स्वागत है!

तैज़ी मूंगफली चिक्की बनाने की मशीन लाइन के चरण

मूंगफली की टॉफी कैंडी बार उत्पादन प्रक्रिया में मूंगफली भूनना→छिलना→चीनी पिघलाना→मिक्सिंग→मूंगफली की कैंडी बनाना→पैकिंग शामिल है। अधिक विवरण के लिए नीचे देखें।

मूँगफली भुनने का यंत्र

मूंगफली कैंडी उत्पादन लाइन में इस मशीन का उपयोग पहले चरण में किया जाता है।

मूंगफली को भूनने से मूंगफली की सुगंध उत्तेजित हो सकती है, इसलिए आम तौर पर मूंगफली के स्नैक्स को भुना जाता है और फिर संसाधित किया जाता है।

मूंगफली भूनने वाली मशीनों के विभिन्न मॉडल हैं, आउटपुट रेंज 80 किग्रा/घंटा-700 किग्रा/घंटा है।

| नमूना | आकार | क्षमता | मोटर | शक्ति | चित्र |

| टीजेडएम-1 | 3*1.2*1.7मी | 80-120 किग्रा/घंटा | 1.1 किलोवाट | 18 किलोवाट |  |

| TZM-2 | 3*2.2*1.7मी | 180-250 किग्रा/घंटा | 2.2 किलोवाट | 35 किलोवाट |  |

| टीजेडएम-3 | 3*3.3*1.7मी | 280-350 किग्रा/घंटा | 3.3 किलोवाट | 45 किलोवाट |  |

| टीजेडएम-4 | 3*4.4*1.7मी | 380-450 किग्रा/घंटा | 4.4 किलोवाट | 65 किलोवाट |  |

| टीजेडएम-5 | 3*5.5*1.7मी | 500-700 किग्रा/घंटा | 5.5 kw | 75 किवॉ |  |

मूंगफली छीलने की मशीन

मूंगफली के छिलके को पूरी तरह से हटाने के लिए मशीन सूखी विधि अपनाती है। लाल छिलका हटाने के बाद मूंगफली का दाना बिल्कुल साफ होता है।

इसकी सफाई दर 96% और क्षमता 200-600kg/h है।

| नमूना | टीजेड-4 | टीजेड-8 | टीजेड-12 |

| शक्ति | 0.75 किलोवाट | 1.5 किलोवाट | 2.61 किलोवाट |

| आकार | 1100*400*1100 | 1100*600*1100 | 1180*900*1100 |

| शुद्ध वजन | / | 200 किलो | 300 किलो |

| कुल वजन | / | 260 किग्रा | 370 किग्रा |

| उपज | 200 किग्रा/घंटा | 400 किग्रा/घंटा | 600 किग्रा/घंटा |

| स्वच्छ दर | 96% | 96% | 96% |

| आधा अनाज दर | 5-20% | 5-20% | 5-20% |

चीनी पिघलाने वाला बर्तन

मूंगफली भंगुर बार उत्पादन लाइन के इस चरण में, यह मुख्य रूप से चीनी को गर्म और पिघला रहा है।

यह मशीन स्टेनलेस स्टील से बनी है, और एक ही समय में गर्म और हिला सकती है।

तापन के तीन तरीके उपलब्ध हैं: बिजली, गैस (प्राकृतिक गैस, तरलीकृत गैस, बायोगैस), और भाप।

आप 50-2000L तक उपयुक्त मॉडल चुन सकते हैं।

| नमूना | मुख्य शरीर का वजन (पैन, बेस, आदि) | सरगर्मी भाग का वजन | ढक्कन का वजन | विद्युत नियंत्रण कैबिनेट वजन |

| 100L | 90 किग्रा | 40 किलो | 7 किग्रा | 5 किलो |

| 200L | 110 किग्रा | 50 किलो | 8 किलो | 7 किग्रा |

| 300 L | 130 किग्रा | 60 किग्रा | 10 किग्रा | 7 किग्रा |

| 400L | 140 किग्रा | 70 किग्रा | 15 किलो | 8 किलो |

| 500L | 150 किलो | 80 किग्रा | 20 किलो | 8 किलो |

| 600L | 160 किग्रा | 90 किग्रा | 30 किलो | 8 किलो |

मूंगफली कैंडी मिक्सर

यह कदम छिली हुई मूंगफली को पिघली हुई चीनी के साथ पूरी तरह मिलाना है। मिक्सर उन्हें जल्दी और समान रूप से मिश्रित कर सकता है।

यह कच्चे माल के तापमान को नियंत्रित करने के लिए एक तापमान नियंत्रण उपकरण से सुसज्जित है। मशीन के अंदर गर्मी संरक्षण का कार्य भी होता है।

मूंगफली चिक्की बनाने की मशीन

मूंगफली भंगुर बार उत्पादन लाइन में, यह मूंगफली कैंडी बनाने की मशीन मुख्य भाग है, और मूंगफली कैंडी को आकार में दबा सकती है। आवश्यक आकार की मूंगफली की भंगुर छड़ें प्राप्त करने के लिए यह हमेशा कटर के साथ काम करता है।

मशीन खरीदते समय, आपको हमें अपने इच्छित उत्पाद का आकार (लंबाई, चौड़ाई और ऊंचाई) बताना होगा। हम आपकी आवश्यकताओं के अनुसार इसे आपके लिए अनुशंसित और अनुकूलित करेंगे।

| नमूना | QY-SCX01 |

| मेज़बान की कुल शक्ति | 380V/50HZ 1.5KW, 220/50HZ 2.5KW |

| विनिर्देश | 8000*1300*1200मिमी |

| मेज़बान का वज़न | 1050 किग्रा |

| उपज | 50-500 किग्रा/घंटा |

| तैयार उत्पाद का वजन | 5 ग्राम-300 ग्राम |

मूंगफली कैंडी पैकिंग मशीन

टैज़ी पिलो पैकेजिंग मशीन का उपयोग कटी हुई मूंगफली कैंडी को 5-200 बैग प्रति मिनट की पैकिंग गति के साथ पैक करने के लिए किया जाता है।

हम आपकी संपूर्ण मूंगफली ब्रिटल बार उत्पादन लाइन के लिए सही पैकेजिंग मशीन की सिफारिश कर सकते हैं।

टैज़ी मूंगफली भंगुर बार उत्पादन लाइन के लाभ

उच्च-क्षमता स्वचालन उत्पादन क्षमता बढ़ाने के लिए

कच्चे माल के प्रसंस्करण, मिश्रण और सम्मिश्रण से लेकर मोल्डिंग और कटिंग तक, पूरी प्रक्रिया कुशलता से चलती है, जिससे उत्पादन क्षमता में काफी सुधार होता है। यह डिज़ाइन ग्राहकों को श्रम लागत बचाने और बड़े पैमाने पर उत्पादन की मांग को पूरा करने में मदद कर सकता है, जो बड़े पैमाने पर खाद्य प्रसंस्करण उद्यमों के लिए बहुत उपयुक्त है।

स्थिर उत्पाद गुणवत्ता और सुसंगत स्वाद

मुख्य उपकरण, जैसे सिरप उबालने वाला बर्तन, मोल्डिंग मशीन और काटने की मशीन, यह सुनिश्चित करने के लिए सटीक नियंत्रण प्रणालियों का उपयोग करते हैं कि मूंगफली कैंडी के प्रत्येक बैच का स्वाद, आकार और आकार समान हो। यह उत्पाद की गुणवत्ता के लिए ग्राहक की उच्च मांग को पूरा करता है। ग्राहकों के लिए, यह स्थिरता ब्रांड प्रतिष्ठा बढ़ाने में मदद करती है।

सुरक्षित सामग्री, खाद्य ग्रेड गारंटी

उत्पादन लाइन 304 स्टेनलेस स्टील से बनी है, जो संक्षारण प्रतिरोधी, साफ करने में आसान और अंतरराष्ट्रीय खाद्य स्वच्छता मानकों को पूरा करती है। यह डिज़ाइन खाद्य सुरक्षा के लिए ग्राहकों की सख्त आवश्यकताओं के अनुरूप है और ग्राहकों को बाज़ार में प्रतिस्पर्धा का लाभ उठाने में मदद करता है।

सरल संचालन और आसान रखरखाव

टैज़ी पीनट ब्रिटल बार उत्पादन लाइन को सरल और संचालित करने में आसान बनाया गया है, ताकि अनुभवहीन कर्मचारी भी जल्दी से काम शुरू कर सकें। इसके अलावा, उपकरण का रखरखाव करना आसान है और भागों को बदलना आसान है, जिससे ग्राहकों को बाद के चरण में संचालन लागत बचाने में मदद मिलती है।

विविध आवश्यकताओं को पूरा करने के लिए लचीला अनुकूलन

मूंगफली कैंडी प्रसंस्करण संयंत्र को ग्राहकों की जरूरतों के अनुसार अनुकूलित किया जा सकता है, जैसे मूंगफली कैंडी के विभिन्न आकार, आउटपुट या अन्य कार्यात्मक मॉड्यूल जोड़ना। यह लचीलापन ग्राहकों को अपनी उत्पाद श्रृंखला का विस्तार करने और विभिन्न बाजारों की जरूरतों को पूरा करने में मदद कर सकता है।

पूर्ण बिक्री के बाद सेवा प्रणाली

हम ग्राहकों को व्यापक बिक्री उपरांत सेवा प्रदान करते हैं, जिसमें उपकरण कमीशनिंग, संचालन प्रशिक्षण, तकनीकी सहायता आदि शामिल हैं। जब तक ग्राहक हमारे उपकरण खरीदते हैं, वे उत्पादन लाइन के स्थिर संचालन को सुनिश्चित करने के लिए हमारी चौकस सेवा का आनंद ले सकते हैं।

मूंगफली भंगुर बार उत्पादन लाइन के कच्चे माल और अंतिम उत्पाद

मूंगफली कैंडी के प्रत्येक उत्पादक का फार्मूला अलग-अलग है। चीनी और मूंगफली का अनुपात अलग होगा और स्वाद भी अलग होगा। मूंगफली कैंडी बार के लिए सामान्य कच्चे माल हैं:

- मूँगफली: उच्च गुणवत्ता वाली मूँगफली जिन्हें छानकर साफ किया गया है और भूना गया है, मूँगफली कैंडी उत्पादन के लिए मुख्य कच्चा माल हैं।

- चीनी: सफेद दानेदार चीनी या माल्टोज़ का उपयोग आमतौर पर मूंगफली की भंगुर पट्टी को मीठा स्वाद और कठोर बनावट देने के लिए एक बांधने की मशीन के रूप में किया जाता है।

- अन्य सहायक सामग्री: स्वाद और स्वाद बढ़ाने के लिए आवश्यकतानुसार तिल, नारियल या मेवे मिलाए जा सकते हैं।

मूंगफली कैंडी अनाज बार उत्पादन लाइन के माध्यम से उत्पादित अंतिम उत्पाद में आम तौर पर शामिल होते हैं:

मूंगफली की कैंडी के टुकड़े, ग्राउंडनट चिक्की बार, तिल की बार, ऊर्जा बार, सचिमा, कैरामेल ट्रीट्स, चावल बार, आदि।

मूंगफली कैंडी बार प्रसंस्करण लाइन की कीमत क्या है?

मूंगफली चिक्की बनाने की मशीन लाइन की कीमत मुख्य रूप से उपकरण विन्यास, आउटपुट मांग और ग्राहक अनुकूलन आवश्यकताओं पर निर्भर करती है। आप जितना अधिक उपकरण कॉन्फ़िगरेशन चाहते हैं और आपके पास जितना अधिक आउटपुट होगा, कीमत उतनी ही अधिक होगी।

जब आप खरीदारी कर रहे हों, यदि आप विशिष्ट मशीन की कीमत जानना चाहते हैं, तो हमसे संपर्क करने का स्वागत है। हम आपकी आवश्यकताओं के अनुसार आपके लिए इष्टतम कॉन्फ़िगरेशन की अनुशंसा करेंगे और आपको एक निःशुल्क कोटेशन भेजेंगे।

अधिक जानकारी के लिए हमसे संपर्क करें!

यदि आप हमारी मूंगफली भंगुर बार उत्पादन लाइन में रुचि रखते हैं, या कोई प्रश्न हैं, तो कृपया बेझिझक हमसे संपर्क करें!

हमारी अनुभवी टीम आपकी आवश्यकताओं के अनुसार समाधान को अनुकूलित कर सकती है और एक कुशल अनाज बार उत्पादन लाइन बनाने में आपकी सहायता कर सकती है। चाहे वह उपकरण का चयन हो, परिवहन व्यवस्था हो, या बिक्री के बाद की सेवा हो, हम यह सुनिश्चित करने के लिए पूरी प्रक्रिया में आपका समर्थन करेंगे कि आपका उत्पादन चिंता मुक्त हो।