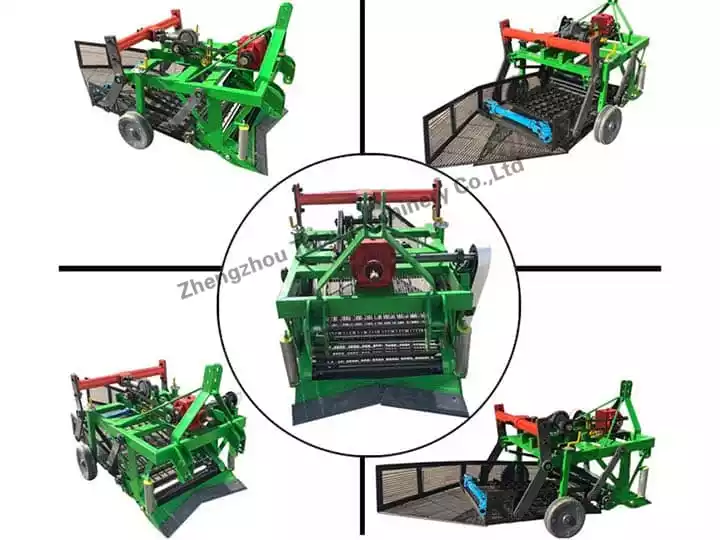

落花生掘り用落花生収穫機

ラッカセイハーベスター |ピーナッツディガー

利用可能なモデル: HS-800、HS-1500、HS-1650

容量: 1300-2000㎡/日(HS-800); 0.15-0.22ha/時(HS-1500); 0.16-0.25ha/時(HS-1650)

収穫率: ≥98%

破損率: ≤1%

清浄率: ≥95%

適合動力: HS-800用30hp; HS-1500用≥80hp

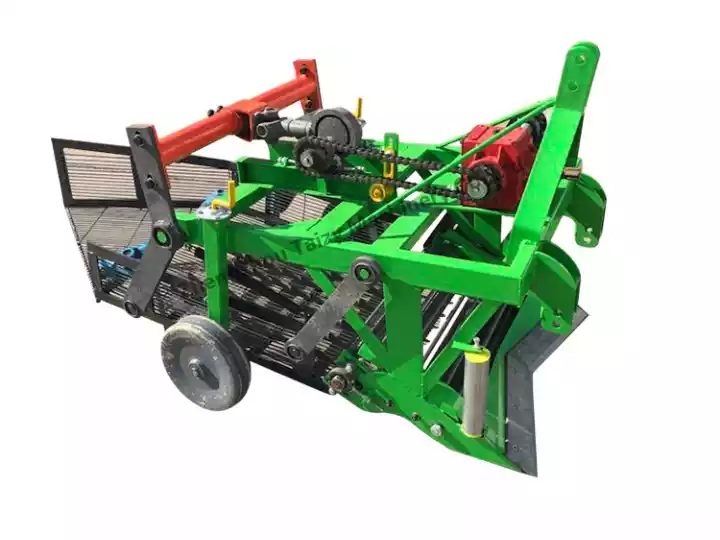

ピーナッツハーベスターは、畑で育ったピーナッツを土から分離するためのものです。トラクターと連動して作動し、収穫率≥98%、破損率≤1%、清浄率≥95%を達成します。

落花生収穫機はHS-800、HS-1500、1650の3タイプをご用意しております。どちらも掘り、土を除き、摘果までの工程で落花生の収穫が完了します。

振動スクリーンとシンプルで簡単な操作が特徴のこのピーナッツディガーは、ナイジェリア、イタリア、セネガル、セントクリストファー・ネイビスなどの国で非常に人気があります。興味のある方は、機械の詳細について今すぐお問い合わせください。

落花生収穫機のメリット

- ≧95%の洗浄率と≧98%の収穫率:きれいに収穫でき、果実のドロップ率も低い。落花生の収穫時に、散らばった落花生をまとめて拾うことができます。

- クライミングチェーン:収穫した落花生を柔軟に搬送できるチェーンを採用した機械です。

- 追加の振動スクリーン: 収穫時、手で摘まなくても落ちた落花生を保管できるので労力が節約できます。

- 可動刃を装備:この設計により、収穫抵抗が最小限に抑えられ、収穫速度が向上します。

ピーナッツ収穫機のパラメータ

当社では HS-800、HS-1500、HS-1650 ピーナッツディガーを販売しています。これらの特定のパラメータはそれぞれ以下に説明されています。

| モデル | HS-800 |

| 容量 | 1300-2000平方メートル/h |

| 梱包率 | ≥98% |

| 破断率 | ≤1% |

| 洗浄率 | ≧95% |

| 重さ | 280kg |

| 家庭用電力 | 30馬力 |

| 収穫幅 | 2列 |

| 列間の距離 | 750~850mm |

| 行間隔 | 180~250mm |

| 寸法 | 2100*1050*1030mm |

| モデル | HS-1500 | HS-1650 |

| マッチングパワー | 37-44kw | 60-81kw |

| 作業幅 | 1500mm | 1600mm |

| 容量 | 0.15~0.22h㎡/h | 0.16~0.25h㎡/h |

| 機械重量 | 450kg | 780kg |

| 機械サイズ | 3140*1770*1150mm | 3830*1990*1340mm |

作付け規模とピーナッツ収穫のニーズに基づいて、どのピーナッツ収穫機を使用するかを決定できます。

サポートが必要な場合は、当社までご連絡ください。お客様のニーズに基づいて最適なソリューションを提供します。

落花生収穫機の機能

落花生収穫機は、手動で落花生の果実を掘る代わりに、地面から落花生を取り出し、掘り出した落花生の苗を機械の側面に置きます。これは、車で直接引き離すのに便利です。

正味回復率は 99% より大きく、剥離率は 1% 未満です。落花生収穫機で加工された後の落花生は世界中にほとんど存在しません。

ラッカセイハーベスタの作用効果

落花生を再度収穫すると、落花生の苗にしっかりとつながっていない落花生が落ちてしまいます。手作業で落花生を収穫するには、1つずつ拾う必要があります。

落花生収穫機は、飛散した落花生を自動的に回収する特殊な構造を持っています。落花生を集めやすいように、すべての落花生の苗を片側に並べます。

落花生収穫機の使い方は?

ピーナッツハーベスターは、適合するトラクターと連動して作業する必要があります。もし、すでにトラクターをお持ちであれば、ご自身のトラクターを直接使用できます。もしお持ちでない場合は、弊社でも適合するトラクターをご用意しておりますので、ご購入をご検討ください。

落花生の列間隔は180~250mmの間で調整可能です。ピーナッツハーベスターの作業深さは3〜5cmです。 1回線でも2回線でも対応可能です。

ピーナッツ収穫後、ピーナッツ収穫機を使ってピーナッツの実を収穫できる場合、ピーナッツ栽培業界でピーナッツプランターを使用できます。これにより、時間と労力をさらに節約できます。

落花生収穫機の構造

- 土を深く掘り、土をほぐすためのシャベル。

- 伝動シャフトはピーナッツ収穫機の伝動装置であり、他の構造を駆動して一緒に移動します。

- ピーナッツを整然と並べるためのとげ。

- 振動ふるいが土から落ちた落花生を回収し、落花生収穫機の回収率を向上させます。

ラッカセイ収穫機の動作原理

ピーナッツディガーは振動スクリーンの原理を採用しています。振盪後、落花生の土を振り落とし、分別して排出するのでリサイクルしやすくなっています。

落花生収穫機の日常メンテナンス

- 作業終了ごとに機械各部の土を取り除き、機械に巻き付いた雑草を取り除きます。

- 各部の留め具を確認し、緩んでいる場合は締め直し、ベルトの磨耗を確認してください。

- 各回転部が柔軟に回転するか確認してください。それが正常でない場合は、時間内に調整して排除する必要があります。

- 長期間使用しない場合は、腐食を避けるために工具を雨から保護し、酸性物質との接触を避ける必要があります。刃には油をさす必要があります!