ピーナッツ核皮むき機用の湿式ピーナッツピーラーマシン

技術的な詳細についてプロジェクト マネージャーに問い合わせることができるようになりました

湿ったピーナッツ皮むき機は、ピーナッツを水に浸し、その後剥くためのものであり、能力は100-250kg/hです。この機械の剥皮率は92%-95%、破損率は2-3%、全体率は85-90%です。

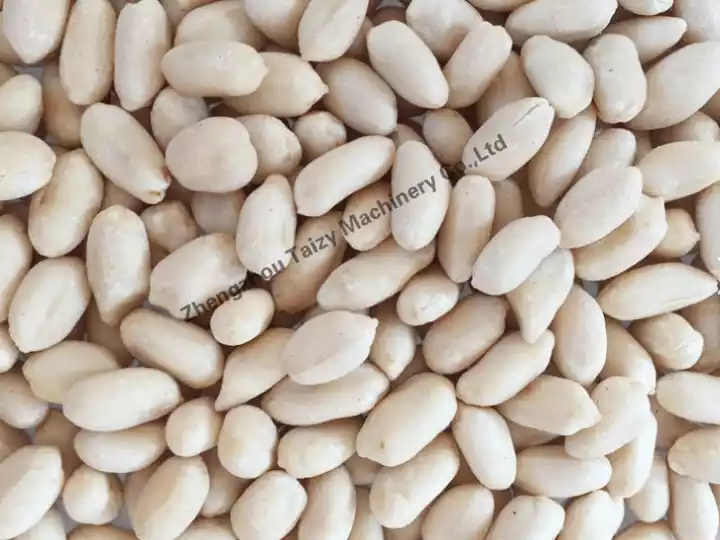

この方法により、ピーナッツは皮をむいた後も純粋で香りが高く、ピーナッツの粒は無傷で白いままであることが保証されます。

湿式ピーナッツ皮むき機に加えて、乾式ピーナッツ皮むき機もあり、ピーナッツの粒を剥く 2 つのまったく異なる方法です。

ピーナッツ皮むき機の利点

- Taizy ピーナッツ皮むき機は湿式皮むきプロセスを採用しており、破損率が低く、皮をむいた後のピーナッツの品質が良好です。

- ピーナッツの皮をむいた後、アーモンドの表面の色は変化せず、タンパク質も失われません。

- 落花生の皮むき工程では、皮と実を自動的に分離して排出できます。

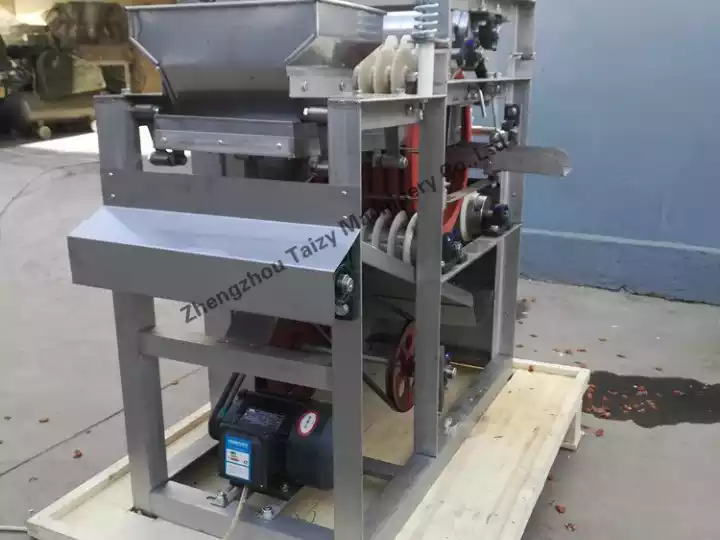

- この機械には、小型、低エネルギー消費、高効率、便利な操作という利点があります。

- この湿式落花生皮むき機は、安定した性能、安全性と信頼性、高い生産性、良好な皮むき効果、および低い半粒率という利点があります。

ピーナッツ皮むき機のパラメータ

| モデル | TZ-100 | TZ-180 |

| 力 | 0.75kw 380v 1.1KW 220v | 0.75kw 380v 1.1KW 220v |

| 剥離率 | 92%-95% | 92%-95% |

| 収率 | 100-150kg/h | 200-250kg/h |

| 完全性率 | 85-90% | 85-90% |

| 破損率 | 2~3% | 2-3% |

| サイズ | 1180×720×1100mm | 1180×850×1100mm |

ご要望をお聞かせいただき、機械のパラメータテーブルと組み合わせて最適なソリューションをご提供いたします。

湿式ピーナッツピーラーマシンの適用範囲

このピーナッツ皮むき機は、ピーナッツを処理するだけでなく、大豆、アーモンド、ひよこ豆などの他のナッツの皮をむくためにも使用できます。皮をむく前に3〜5分間浸す必要があります。

このようにして、赤い皮とピーナッツの粒はあまりフィットせず、それらの間に一定の隙間が残るため、ピーナッツの皮を剥くときに濡れたピーナッツピーラーマシンがピーナッツを傷つけたり損傷したりすることはなく、浸した後の皮むき効率も向上します。も改善されます。推進する。

ピーナッツ皮むき機の使い方は?

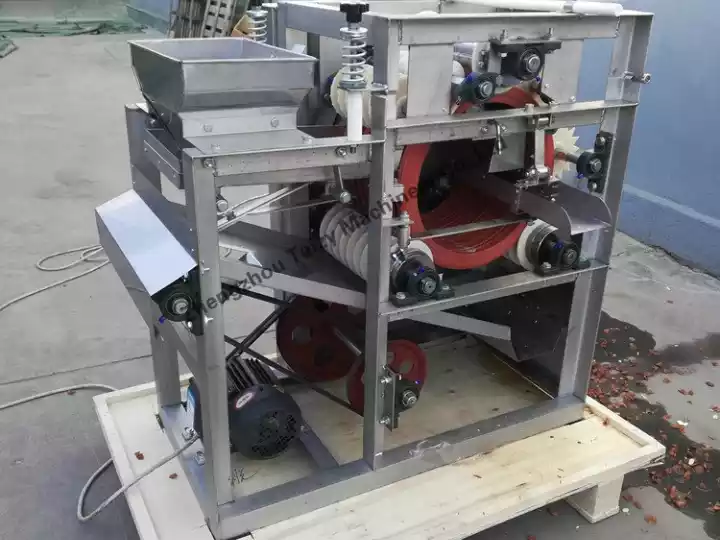

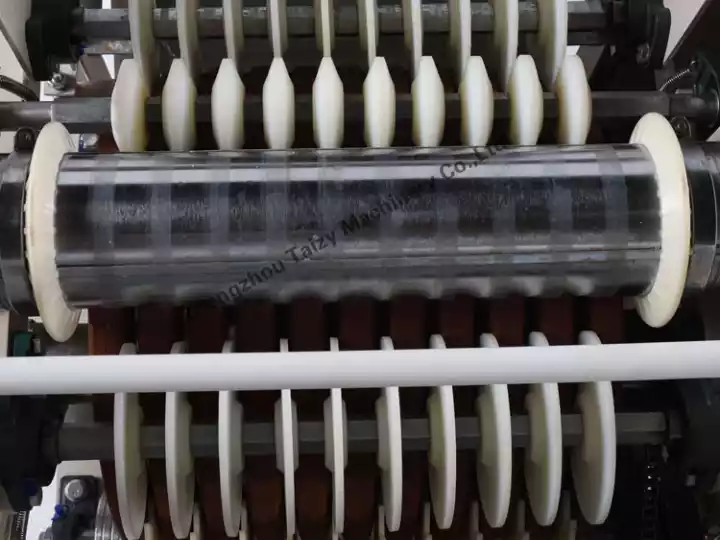

湿式ピーリングでは、主に落花生を温水に 3 ~ 5 分間浸した後、ホッパーに注ぎます。ピーナッツを振ると、回転するゴムローラーの中に入ります。

ゴムリングが擦れた後、落花生の赤い皮が取り除かれ、別の排出口から排出され、皮と粒が自動的に分離されます。

その主な技術パラメータは、剥離率: 98%±2、破損率: 3% 未満、および全カーネル率: 90%±5 です。

ピーナッツピーラーマシンの原理

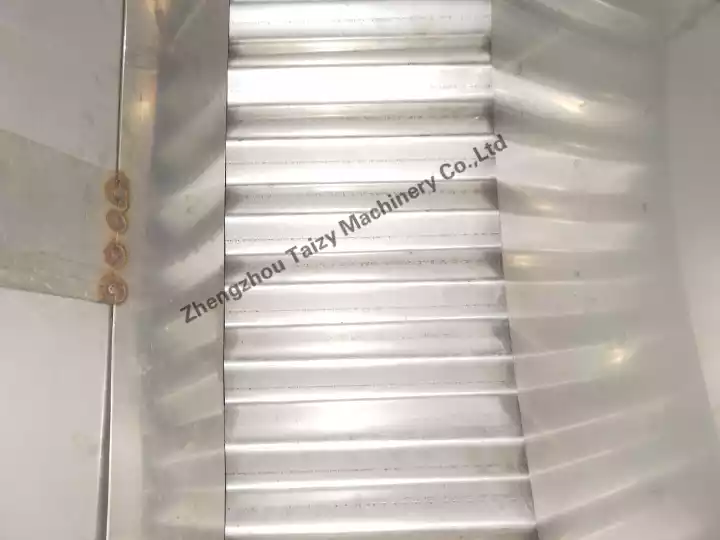

湿式落花生皮むき機は、浸漬した落花生を、供給機構を介して隣接する 2 つのゴム製摩擦リング間の隙間に送り込みます。リングの隙間では摩擦が進みます。

プレスホイールとリミットライトバーに摩擦が進むと、剥かれた落花生は螺旋状の排出シュートに落下し、スクリューシャフトにより反転材に送られて排出口から排出されます。

皮をむいたピーナッツ 水のフラッシング作用により、赤皮は赤皮引き出しホイールから材料ホイールの後ろの赤皮出口トレイに移送され、リミットライトバーから排出されます。

Shuliyの会社紹介

Shuliyは20年以上にわたりピーナッツ加工機械に従事してきました。同社は、ピーナッツ植え付け機、ピーナッツ収穫機、ピーナッツ殻取り機、ピーナッツ油圧プレスなど、ピーナッツ加工用の多くの農業生産機械を取り揃えています。その中でも、ピーナッツ殻取り機は非常に人気があります。

関連するピーナッツ機械が必要な場合は、機械の詳細についてお気軽にお問い合わせください!