땅콩 껍질 제거 기계 | 땅콩 크래킹 기계

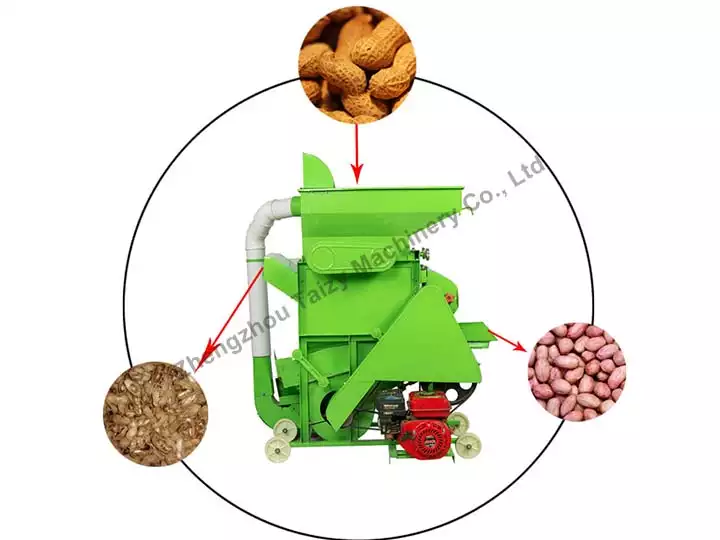

땅콩 껍질 제거기는 땅콩 껍질을 벗기는 기계입니다. 땅콩이 수확되고 건조된 후에 땅콩 껍질을 제거해야 합니다. 이 땅콩 껍질 제거기는 작고 가벼워 언제든지 이동할 수 있습니다. 땅콩 껍질 제거 효과가 좋기 때문에 인기가 있습니다. 이 땅콩 껍질 제거기는 가족 농장, 기름 공장, 땅콩 씨앗 공장 및 땅콩 식품 공장에서 사용할 수 있습니다. 이것은 작은 땅콩 껍질 제거기이며, 우리 회사는 땅콩을 동시에 청소하고 껍질을 벗길 수 있는 대형 땅콩 깨는 머신도 보유하고 있습니다.

땅콩 크래킹 기계의 적용 범위

이 땅콩 껍질 제거 기계는 석유 공장에서 사용할 수 있습니다. 사용 시 석유 공장에서는 일반적으로 땅콩 껍질 제거기를 사용하여 가공한 다음 스크류 프레스를 사용하여 땅콩 기름을 짜냅니다. 땅콩 공장에서 코팅 땅콩 및 땅콩 사탕과 같은 땅콩 스낵을 만드는 데 사용할 수 있습니다. 가족 농장에서도 사용할 수 있으며 작동이 매우 간단하고 어디든 이동할 수 있습니다.

땅콩 탈곡기의 매개변수

| 모델 | TBH-800 |

| 전반적인 차원 | 1330*750*1570mm |

| 순중량 | 160kg |

| 생산력 | 600-800kg/h |

| 파손율 | ≤2.0% |

| 피해율 | ≤3.0% |

| 박리율 | ≥98% |

| 힘 | 3kw, 220v, 50hz, 구리 모터 |

| 기능 | 땅콩 껍질 벗기기 |

땅콩껍질 제거기의 구조

땅콩 껍질 벗기기 기계는 프레임, 팬, 로터, 단상 모터, 스크린 (두 가지 크기가 있음), 공급 호퍼, 진동 스크린, V 벨트 및 그 전송 V 벨트로 구성됩니다. . 땅콩을 껍질을 벗긴 후에는 껍질을 벗긴 후 깨끗한 속도를 보장하기 위해 땅콩 알맹이의 불순물을 제거하는 팬이 있습니다.

땅콩 껍질 제거 기계의 작동 원리

로터의 충돌로 땅콩이 통째로 깨집니다. 스크린을 통과한 후 팬에게 떨어집니다. 팬의 부는 힘으로 가벼운 땅콩 껍질이 땅콩 껍질 벗기기 기계에서 날아가고 땅콩 커널이 땅콩 껍질 벗기기 기계에서 배출됩니다. 유출. 기계가 정상 작동된 후 땅콩을 공급 호퍼에 정량적으로, 균일하고, 연속적으로 넣으면 반복적인 타격, 마찰 및 로터의 충돌로 땅콩 껍질이 깨집니다. 회전하는 풍압과 로터의 바람에 의해 땅콩 알갱이와 깨진 땅콩 껍질이 구멍이 있는 스크린을 통과합니다.

이때, 땅콩 껍질과 과립은 회전하는 팬의 송풍력을 받게 되며, 가벼운 땅콩 껍질은 기계 본체 밖으로 불어지고, 땅콩 과립의 청소 목적은 스크리닝을 통해 달성됩니다. 진동 스크린.

땅콩 껍질을 개선하는 방법은 무엇입니까?

땅콩 껍질 제거제의 최상의 효과를 얻으려면 땅콩을 적절하게 건조하고 적시는 것이 필요합니다. 땅콩이 너무 건조하면 땅콩의 분쇄율이 높아지고, 땅콩이 너무 젖으면 땅콩 껍질의 효율이 영향을 받습니다. 10시간 전에 따뜻한 물 10kg을 땅콩 50kg 표면에 뿌려주면 됩니다. 이렇게 하면 필링 효과가 향상됩니다.

땅콩 크래킹 기계의 장점

- 땅콩 껍질 제거 기계는 컴팩트한 구조, 쉬운 작동, 안정적이고 신뢰할 수 있는 성능을 가지고 있으며,

- 껍질 제거 효율이 높고 땅콩 알맹이의 파쇄 속도가 낮으며 분류가 양호하고 손실률이 낮습니다.

- 99%는 불순물이 깨끗하고 껍질이 벗겨지는 비율이 적으며, 땅콩 파손율은 1% 이하입니다.

- 저소음, 이동이 용이한 땅콩 크래킹 기계에는 롤러가 있어 어디든 이동할 수 있습니다.

땅콩 껍질 제거 기계를 사용하는 방법은 무엇입니까?

사용하기 전에 패스너가 조여져 있는지, 대형 땅콩 껍질 벗기기 기계의 회전 부분이 유연한지, 각 베어링에 윤활유가 있는지, 땅콩 크래킹 기계가 안정된 바닥에 배치되어야 하는지 여부를 확인하십시오. 사용하기 전에 전원 공급 장치와 땅콩 껍질 벗기기 기계를 확인하십시오. 땅콩 크래킹 기계의 스위치는 꺼짐 위치에 있어야 합니다. 모터가 시동된 후 로터의 회전은 기계에 표시된 방향과 일치해야 합니다. 작은 땅콩 껍질 벗기는 기계는 비정상적인 소리가 있는지 관찰하기 위해 몇 분 동안 유휴 상태여야 합니다. 땅콩을 먹이세요.