Cocoa butter production line

| Name | Cocoa butter production line |

| Finished product fineness | 200mesh |

| Process | Roasting→peeling→grinding→Homogenizing |

| Required machines | Cocoa bean roaster, peeler, grinder, etc. |

You can now ask our project managers for technical details

The cocoa butter production line is a fully automated cocoa paste production unit comprised of multiple machines. It processes cocoa beans into cocoa paste through a multi-step process. Its functions include roasting, peeling, and grinding the cocoa beans into cocoa paste.

Taizy cocoa paste production line has a production capacity of up to 2,000 kg/h. The line includes cocoa roaster, cocoa bean peeler, grinder, and elevator. These machines work in tandem, resulting in significantly higher efficiency.

Characteristics of the cocoa mess production line

- Full-line automatic control: From raw material feeding, grinding, mixing, homogenization, degassing, filling, all operations can be automated to reduce labor costs.

- Continuous production process: Materials flow within a closed system, preventing contamination and achieving high production efficiency.

- High-quality finished product: The cocoa paste produced by the cocoa paste production line is more delicate and avoids clumping during the production process.

- Made of food-grade materials: The entire line is made of stainless steel or carbon steel, which is corrosion-resistant, easy to clean, and meets food machinery hygiene standards.

- Safety fire protection system: Our cocoa butter production line can be equipped with a carbon dioxide fire protection system according to customer needs.

Applications of peanut butter

- Chocolate manufacturing: Cocoa paste is a core ingredient in chocolate production and can be used to make a variety of products, including pure chocolate, milk chocolate, and filled chocolates.

- Bakery industry: Cocoa paste is widely used as a filling, decoration, and flavoring in baked goods such as cakes, cookies, bread, and mousse.

- Beverage processing: Cocoa paste can be used to prepare cocoa drinks, chocolate milk, milkshakes, and ice cream drinks, adding a rich flavor and mouthfeel.

- Confectionery: Cocoa paste is commonly used for wrapping, filling, and coating confectionery products, such as chocolate chips and bonbons.

- Dairy Processing: Many dairy companies use cocoa paste to enhance the flavor and color of products such as yogurt, ice cream, and cream.

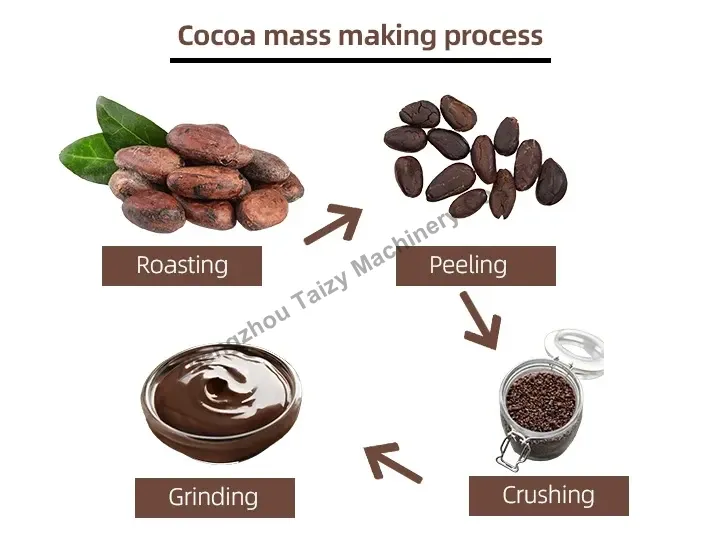

Cocoa butter production process

The main processes of cocoa butter production include roasting, peeling, grinding, homogenizing, storage, etc.

- Roasting: The cocoa beans are roasted evenly to remove excess moisture and bring out the cocoa aroma.

- Peeling: After roasting, the cocoa beans are crushed and peeled to separate the cocoa kernels and remove impurities from the shell to ensure the purity of the finished product.

- Grinding: Grind the cocoa kernels into fine cocoa liquid to fully release the fat in them, forming the basic form of cocoa paste.

- Homogenizing: Processing cocoa paste with a homogenizer can make the particles finer and improve the taste.

- Storage: The processed cocoa paste is stored and protected from oxidation in mixing tanks, vacuum tanks, and storage jars.

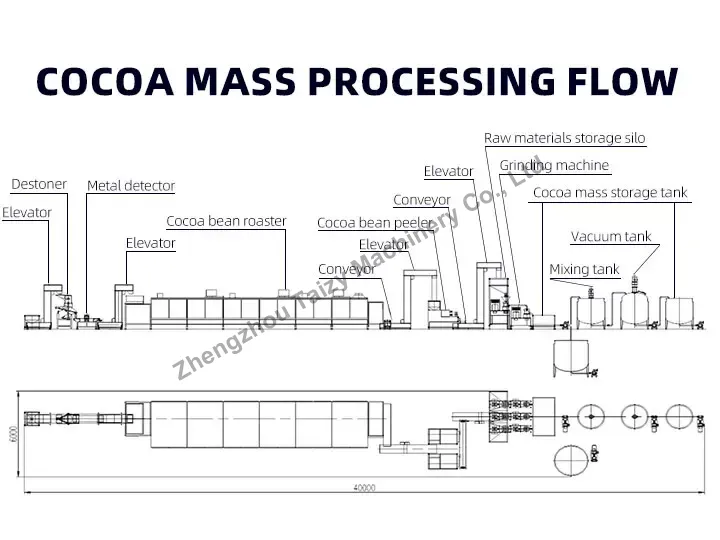

Machines in the cocoa butter production line

The machines in the cocoa paste butter processing line include:

- Z-shaped elevator

- Cocoa bean roasting machine

- Cocoa bean peeling machine

- Ccocoa bean grinding machine

- Homogenizer

- Cocoa paste storage jar

Z-shaped elevator

In the cocoa butter production line, the Z-shaped elevator is used to automatically load cocoa beans, saving labor and improving production efficiency.

The Z-shaped elevator consists of hopper and Z-shaped conveyor mechanism, using a vibrating feed mechanism. It is made of stainless steel, which is more in line with hygiene standards. Its parameters are as follows:

| Machine name | Z-shaped elevator |

| Power | 0.75kw |

| Machine size | 2500x700x3000mm |

| Material | Stainless steel |

Cocoa bean raoster

The function of the roaster on cocoa beans is to evenly heat and roast the cocoa beans to remove moisture. In the cocoa paste production line, we use a chain-link roasting machine.

It can be equipped with the siemens control cabinet, which enables precise temperature and time control, automatic start and stop, and fault alarms, ensuring a stable and consistent baking process. Its parameters are as shown below:

| Machine name | Chain-link roaster |

| Power | 30kw |

| Machine size | 15000x3250x2550mm |

| Material | Carbon steel (customizable stainless steel) |

| Heating method | Gas heating and electric heating |

The cocoa bean roasting machine can also be equipped with an optional CO₂ fire suppression system, providing fire protection in high-temperature environments and effectively enhancing equipment operational safety.

Cocoa bean peeling machine

The cocoa bean peeling machine is used to efficiently separate the shells from the cocoa nibs after roasting. The equipment utilizes a three-step system: roller dehulling, vibrating grading and screening, and air separation, working in tandem to achieve the following functions:

- Shell separation: Counter-rotating drums gently press the cocoa beans to crack the shells.

- Grading and screening: Vibrating screens evenly disperse and pre-grade the crushed material, improving separation efficiency.

- Air Separation: By adjusting the appropriate air pressure, the shells are removed, leaving behind pure cocoa nibs.

The machine is easy to operate and offers excellent separation performance, effectively improving the purity of raw materials, and is an important machine in the cocoa butter production line. Its parameters are as follows:

| Model | TZ-1 | TZ-2 | TZ-3 | TZ-4 |

| Capacity | 50-100kg/h | 200kg/h | 300kg/h | 400-500kg/h |

| Power | 0.4kw | 0.75kw | 0.75 | 2.2kw |

| Peeling rate | / | >98% | >99% | >99% |

| Machine wieght | / | 140kg | 200kg | 280kg |

Cocoa bean grinding machine

The cocoa paste grinder uses high-speed relative motion between the stator and rotor to rub and grind the cocoa beans. This process breaks down the cell walls, releasing the cocoa paste, ultimately creating an extremely fine and smooth liquid paste. The grind fineness can reach 200 mesh.

Its parameters are as listed below:

| Machine name | Cocoa bean grinding mahcine |

| Power | 30kw |

| Machine size | Cocoa bean grinding machine |

Homogenizer

The cocoa paste homogenizer is one of the equipment in the cocoa butter production line. It is mainly used to further homogenize the ground cocoa paste. This process makes the particles in the cocoa paste finer and more evenly distributed, thereby improving the smoothness and taste of the cocoa paste.

Its parameters are as follows:

| Machine name | Homogenizer |

| Power | 37kw |

| Machine size | 1350*1200*1520mm |

| Material | 304 stainless steel |

Cocoa paste storage jar

The cocoa paste storage system consists of mixing jar, vacuum jar, and storage jar. It is used for constant temperature storage, anti-oxidation, and anti-stratification of cocoa paste. It is an important post-processing equipment in the cocoa butter production line.

- The mixing tank is mainly used to maintain the uniformity of the cocoa paste.

- Vacuum tanks are used to degas and prevent oxidation of cocoa paste.

- The storage tank serves as a temporary holding vessel for cocoa paste at the end of the production line. Its primary function is to ensure continuous filling operations.

FAQ of cocoa butter production line

How fine can cocoa paste be?

200 mesh.

Is the equipment operation complicated?

Easy to operate. Equipped with a PLC touch screen control system, one-button start or stop.

What are the heating methods of the toaster?

Electric heating and gas heating. It is recommended to use gas heating (more economical than electric heating)

Can the cocoa butter production line be customized?

Yes. We can customize a complete line solution based on your production volume, site layout, and other factors, providing layout design and technical guidance.

Why choose Taizy as your preferred supplier?

- Extensive industry experience: Taizy possesses years of expertise in cocoa paste and chocolate processing equipment, and has successfully delivered efficient production lines to clients across multiple countries and regions worldwide.

- High-quality equipment and technology: Equipment utilizes food-grade materials, offering corrosion resistance and easy cleaning. Advanced homogenization, grinding, and automated control technologies are integrated.

- Production safety: Clients can choose to equip the roasting stage with a carbon dioxide or inert gas fire suppression system for effective fire prevention and production safety.

- Customization and flexibility: We provide personalized designs and customized solutions based on client production volume requirements, process recipes, and site layouts.

- Comprehensive after-sales support: We provide operational training, technical assistance, and maintenance services. Additionally, we can design machine layout drawings tailored to your facility.

Contact us now!

Taizy offers efficient, automated cocoa butter production lines. We also provide a variety of food processing solutions, including peanut butter production line and peanut oil production line.

Our team of experts is always available to provide free technical consultation and customized solutions, tailoring the most optimal production plan to your needs. Contact us today and let Taizy help you efficiently produce high-quality food products and enhance your market competitiveness.