Almond shelling production line

| Model | Taizy |

| Capacity | 1000kg/h |

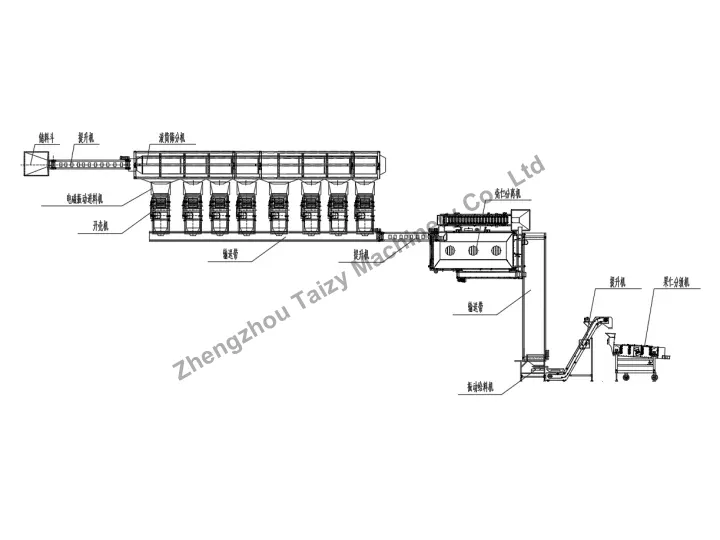

| Process | Almond grading → almond shelling → shell and kernel separation → kernel grading |

| Required machines | Grading machine, feeding hopper, almond sheller, shell and kernel separator, kernel grading machine, etc. |

You can now ask our project managers for technical details

Our almond shelling production line integrates functions for almond grading, shelling, shell-kernel separation, and kernel grading. Besides processing almonds, it can also be used to process various nuts, such as walnuts, pecans, and hazelnuts.

The Taiz almond processing line features continuous operation, labour savings, and high efficiency, with a production capacity of 1,000 kg/hour. This production line is widely used in the food industry and the nut processing industry.

Advantages of almond cracking and shelling line

- High degree of automation: The almond shelling line integrates almond grading, shelling, shell and kernel separation, and kernel grading into one system, reducing manual labor, effectively lowering labour costs.

- Stable shelling performance: By pre-grading the almond kernels, precise shelling can be performed on kernels of different sizes, ensuring a high shelling rate while maximizing the integrity of the almonds.

- High kernel yield: The shell-kernel separation process effectively removes shell impurities, resulting in cleaner finished almonds and reducing the need for subsequent manual sorting.

- Wide range of applications: This almond shelling line can process various varieties and sizes of almond kernels, as well as walnuts, pecans, hazelnuts, and other nuts, catering to diverse production needs.

- Continuous operation: The entire line works collaboratively to achieve long-term continuous operation, ensuring production stability and improving production efficiency.

Main steps of almond shelling

Our almond shelling line organically combines multiple processes to achieve continuous and stable operation. Its main steps include: Almond grading → almond shelling → shell and kernel separation → kernel grading.

Primary equipment for almond shelling production line

Taizy almond shelling line mainly consists of the following equipment:

- Elevator

- Drum grading machine

- Electromagnetic quantitative feeding hopper

- Almond shelling machine

- Shell and kernel separator

- Kernel grading machine

Elevator

This elevator can lift almonds to a specified height and transport them to subsequent equipment, thereby reducing manual feeding. Its specifications are as follows:

- Power: 2.2kw

- voltage: 380v,50hz, three phase

Drum grading machine

The rotary drum screening machine sorts apricot kernels by size, providing uniformly sized raw materials for subsequent shelling machines. Its data is as follows:

- Size:: 5.5*1.1*2.5m

- Capacity: 1000kg/h

- Weight: 2300kg

- Power: 2.2kw

- Voltage: 380v 50hz three phase

- Material: Drum hopper stainless steel, other carbon steel

Electromagnetic quantitative feeding hopper

The feeder provides a stable supply of graded almonds, ensuring that the material enters the shelling equipment at an appropriate speed. Its detailed specifications are as follows:

- Size: 1*1*1.6m

- Power: 0.05kw

- Material: Stainless steel

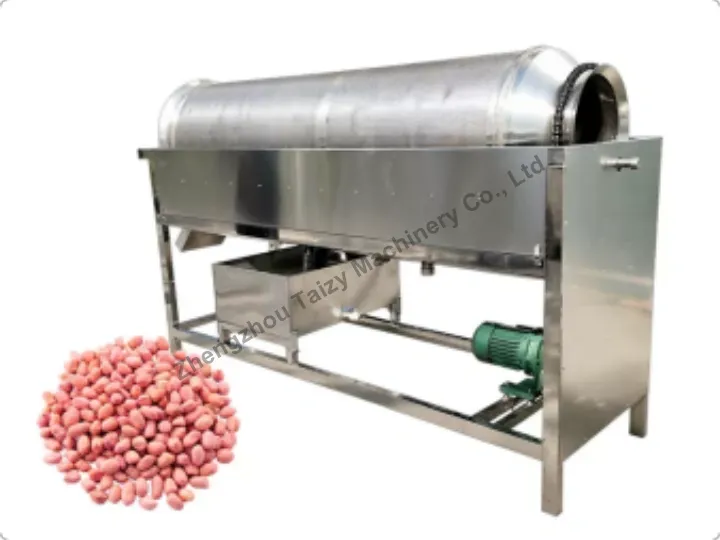

Almond shelling machine

The almond shelling machine, as a core component, is used to break open the almond shells. Its technical parameters are as follows:

- Size: 2100*900*1300mm

- Power: 3kw

- Voltage: 380v 50hz three phase

- Weight: 280kg

Shell and kernel separator

The shell and kernel separating machine can separate the nut shells from the kernels. This machine can be designed and customised according to production capacity and raw material size.

- Size: 2.6*1.1*1.6m

- Power: 1.5kw

- Voltage: 380v 50hz three phase

Kernel grading machine

The kernel grading machine sorts the separated almond kernels into five grades based on size or integrity, facilitating the packaging or further processing of different grades of product.

- Size: 1500x800x1250mm

- Power: 0.75kw

Application of almond shelling production line

Our almond processing line has a wide range of applications. In addition to processing almonds of different sizes, it can also be used to process various shelled nuts such as hazelnuts, bada nut and macadamia nuts.

FAQ of alomond cracking and shelling line

How many almonds can this production line process per hour?

1000kg/h.

Can the almond shelling production line process almonds of different sizes?

Taizy almond shelling line can process almonds of different sizes.

Can the production line be customised according to my specific needs (such as the size of the site)?

Customised services are available.

Does Taizy provide installation and operation training services?

On-site installation requires customer-covered accommodation and meals; videos and online guidance are free.

How long is the production time for this processing line?

25-35 working days.

Successful cases of Taizy almond shelling production line

Recently, our almond shelling line was successfully exported to Uzbekistan. The customer reported that the line operates stably, the almond shelling effect is ideal, and the finished product has high integrity.

Our customer also stated that the almond shelling line meets their long-term processing needs and provides reliable support for future expansion of almond processing.

Contact us immediately!

If you are looking for a reliable almond shelling production line to improve processing efficiency and product quality, feel free to contact us immediately. Our team will provide professional solutions for you!