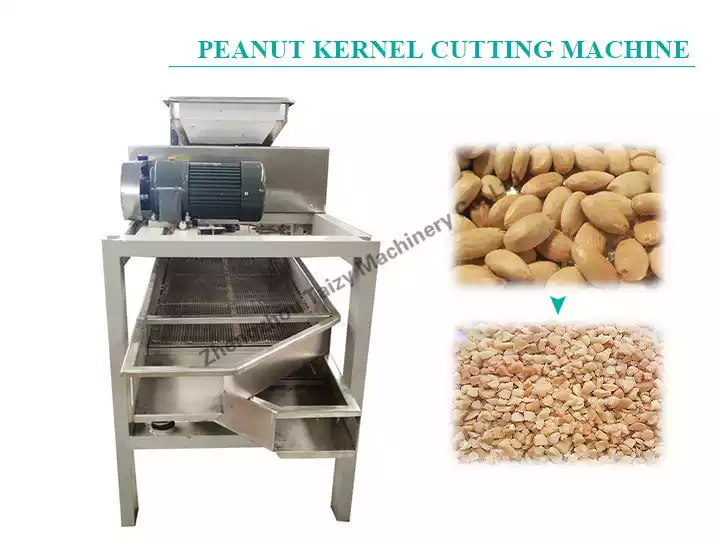

Dry peanut peeling machine for roasted groundnut skin removal

Groundnut Peeling Machine | Roasted Peanut Peeler

Machine brand: Taizy

Capacity: 200-1000kg/h

Moisture content: <5%

Peeling rate: 98%

Voltage: 380V/220V 50HZ

Application: Used in the peanut brittle bar or peanut butter making line

Peanut peeling machine is designed to remove the red coat of roasted peanuts, usually used in the peanut brittle bar making machine line or peanut butter processing line. It’s better to use this machine when the moisture content is <5%.

This roasted peanut peeler has a capacity of 200-1000kg/h and a peeling rate of 98%. Featuring high efficiency and dry peeling method, this equipment is popular in the groundnut processing industry.

The peanuts will be hulled after picking the fruit and can be used for seeds and other purposes after the hulling, but the red peanut skin needs to be removed in general peanut processing. The peanut peeler will have a better-peeling effect after roasting.

Attractive strengths of groundnut peeling machine

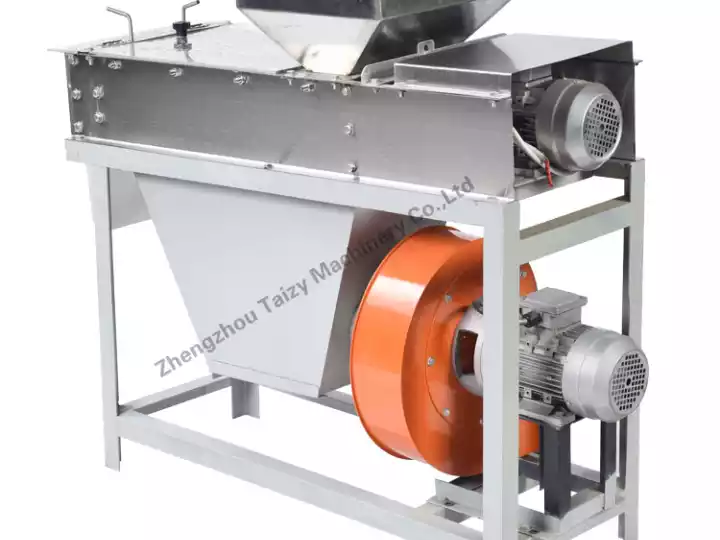

- Automatic separation. Peanut skins and peanuts are automatically separated.

- Small and easy to move. English instructions and video teaching will be sent.

- High peeling rate. After peeling peanuts, the peeling rate of peanuts reaches 99%.

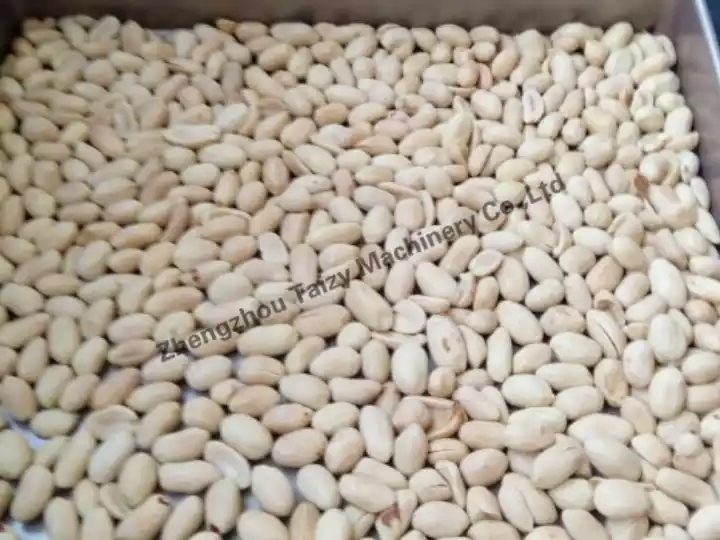

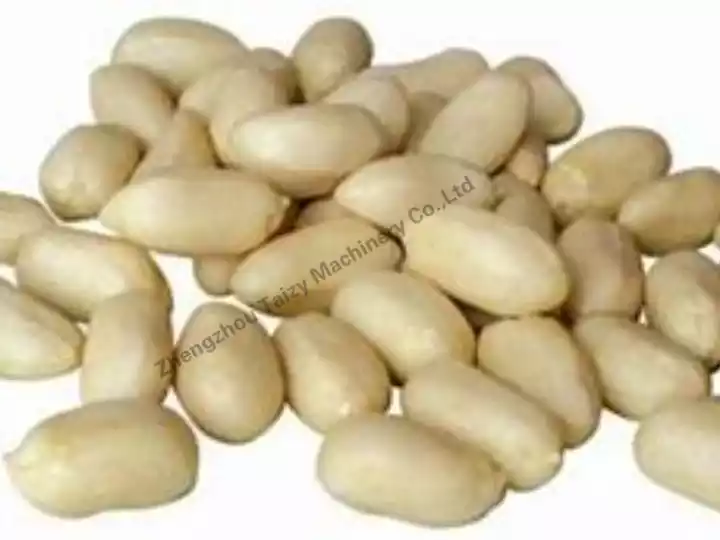

- Good peanut peeling effect. Peanuts are still intact after peeling, and the shape of the peanuts will not be damaged.

Parameters of peanut peeling machine

| Output | Motor power | Fan power | Voltage | Frequency | Removal rate | Dimensions |

| 200-300kg/h | 0.55kw | 0.37kw | 380V/220V | 50HZ | 98% | 1100*400*1100MM |

| 400-500kg/h | 0.55kw*2 | 0.37kw | 380V/220V | 50HZ | 98% | 1100*700*1100MM |

| 600-800kg/h | 0.55kw*3 | 0.37kw | 380V/220V | 50HZ | 98% | 1100*1000*1100MM |

| 800-1000kg/h | 0.55kw*4 | 0.37kw | 380V/220V | 50HZ | 98% | 1100*1400*1100MM |

As can be seen from the above parameter table, our groundnut peeling machine can match a wide range of production, which is mainly determined by your specific needs. If you want to produce large quantities of peanut candy, then the equipment you need must be large. Then the 600-1000kg/h model is most suitable for you.

If you have any questions about which model to choose or about the equipment, contact us and we will answer them for you.

The use of roasted peanut peeler machine

The moisture content of baking is preferably less than 5%. The lower the moisture content, the better the peanut peeling effect, which is completely opposite to the use method of the wet peanut peeling machine.

When purchasing the machine, you can choose whether to peel the peanuts dry or wet according to the humidity of the peanuts.

Structure of peanut peeling machine

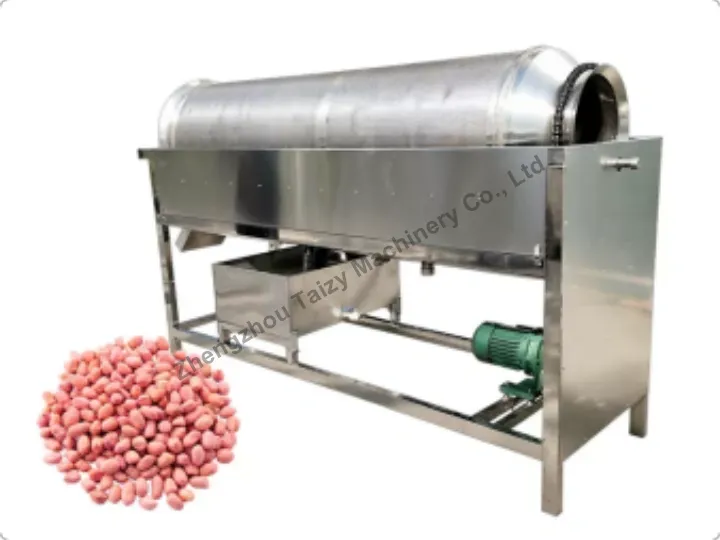

The peanut peeler machine is composed of a power device (including motor, pulley, belt, bearing, etc.), frame, feeding hopper, peeling roller (steel roller or sand roller), suction fan, etc.

Application fields of peanut peeling machine

It is used in the pre-peeling treatment for the production of fried peanuts, flavored peanuts, peanut cakes, peanut candy, peanut milk, peanut protein powder, eight-treasure porridge, sauce peanuts, and canned products.

The principle of the peanut skin remover equipment

After the groundnut peeler is in normal operation, the peanuts can be put into the hopper evenly and continuously, and the peanut peel and peanuts will be separated under the repeated friction of the rotor. Then the fan in the machine will blow out the lighter peanut skins to achieve the purpose of separation.

Why do peanuts need to remove the red skin?

Peanuts have a layer of red skin, which generally needs to be removed during peanut brittle making or peanut butter processing plant, because the red skin of peanuts is relatively bitter, and it will affect the taste when made into food.

Peanut skins are also removed when used as nuts in biscuits and cakes. Peanuts also need to be peeled for making peanut butter, so peanut peeling machines are important machines in the peanut processing industry.

Get a quote now!

In the process of peanut, if you are interested in peanut peeling, contact us, and tell us your needs(such as production, budget, peanut humidity, etc.), and we will recommend the most suitable solution and provide the best price for you according to these.